Water Resource Preservation

Policy

Asahi Kasei Group's business is intrinsically related to water resources. Ensuring their future viability is one of our societal missions and a prerequisite for the continuity of our business. We will contribute to the conservation of water resources around the world through our domestic and overseas filtration membrane module business (water supply, seawater desalination, etc.), the development of sludge reduction products for wastewater treatment, and the expansion of our surface oil detector series. We also have a policy of ascertaining the quantity of our water intake while striving to maintain and improve the efficiency of our water usage.

Reducing water use

The Asahi Kasei Group endeavors to reduce the amount of water used in our plants and to make efficient use of water by recycling it.

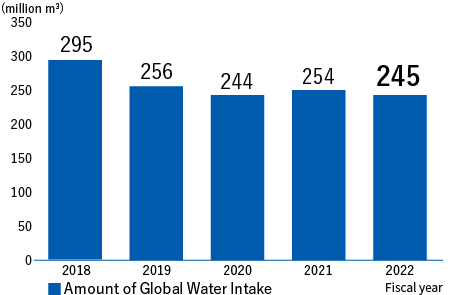

Amount of Global Water Intake

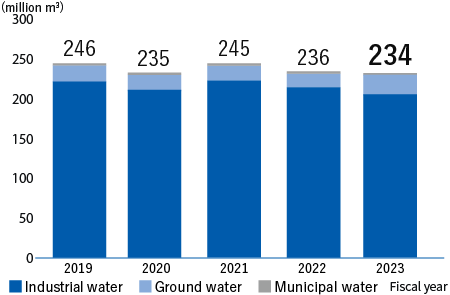

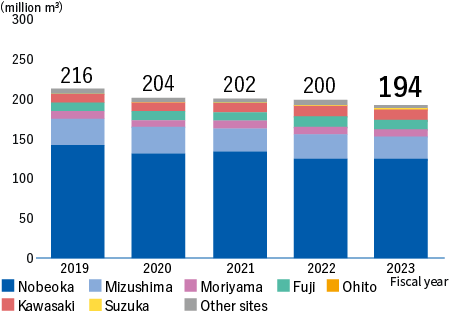

Amount of Global Water Intake Amount of Water Intake by Source (domestic)

Amount of Water Intake by Source (domestic)

Actions in the Moriyama Area

All water used at our Moriyama Works is drawn from groundwater systems. This water is primarily used as a coolant to cool machinery and equipment via heat exchange, but we are also promoting the reuse of the water we draw. The water reuse rate in fiscal 2022 was 2.3 times the amount of water intake. We will continue working to reuse water within our Moriyama Works, from the perspective of long-term water resource security.

Prevention of water pollution

The Asahi Kasei Group is thorough in its water discharge management and leakage countermeasures in order to prevent contamination of bodies of water or groundwater. In addition, as an annual goal for group-wide environmental safety activities, we have set zero instances of leakage as covered by the Water Pollution Prevention Act.

In 2012, we issued our Guidelines on Wastewater Management. In addition to affirming our commitment to wastewater management based on this, we are also working on enhancing the capacity of wastewater treatment facilities and other equipment.

The Asahi Kasei Group sets voluntary management targets for the quality of wastewater from our offices and plants, managing water quality to a higher level than wastewater regulation standards.

In fiscal 2022, there were neither instances of leakage as related to the Water Pollution Prevention Act nor violations or fines related to environmental laws and regulations.

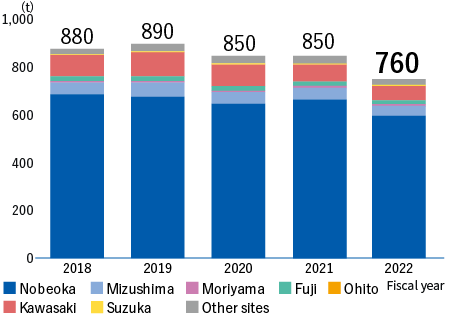

Amount of Wastewater (domestic)

Amount of Wastewater (domestic) Chemical Oxygen Demand (COD) Load

Chemical Oxygen Demand (COD) Load

Asahi Kasei products and technologies for water conservation

Microza™ hollow fiber membrane filtration module

We are a top-tier supplier of water treatment membranes and filtration systems. Microza™ is a hollow fiber membrane we have developed for water treatment. It is used in more than 1,600 water purification plants and wastewater plants worldwide, including in the United States, China, Korea, Singapore, Thailand, Indonesia, and Middle Eastern countries. Singapore’s NEWater, Asia’s largest wastewater reclamation plant, has continued to use this product since 2007.

Going forward, we will continue to work on global water and environmental issues with the aim of resolving various problems related to water resources.

Saran™ Polyvinylidene Chloride Fiber

One important issue in wastewater treatment is reducing the amount of sludge generated, which is directly tied to decreasing its environmental impact. The Asahi Kasei Group conducts research and development into new commercial products that feature a unique technology using microorganism immobilized carrier that flows, making use of the characteristics of Saran™ fiber, which microorganisms inhabit easily.

Existing facilities can adopt these products by making simple improvements like installing screens, without requiring major modifications. This improves processing capabilities and reduces the amount of sludge generated.

Apolarm™ series environmental monitoring products

Asahi Kasei Technosystem's Apolarm™ Series detects a wide range of oil leaks, including floating oil (oil film and oil layers), sediment oil, and water-soluble oil. We will continue to expand our product line and protect the aquatic environment with oil detection devices for specific applications.

| Apolarm C | Oil layers of 3 mm or more trigger a capacitance shift and sound an alarm. |

|---|---|

| Apolarm M | A non-contact laser detector that can sense minuscule amounts of oil film on the water surface. |

| Apolarm B | Detects oil and organic solvents that have a greater specific gravity than water, causing them to sink. |

| Apolarm F | Detects leakage of fluorescent water-soluble oils. |