100 Stories1931, Bemberg™, the Inherited Business—Not Only Applied in Apparel But Also Healthcare

Bemberg™ is one of Asahi Kasei’s inherited businesses. It is used in Uniqlo’s functional innerwear, AIRism. Bemberg™ has a profound history. Its production started in 1928 when the Germany-based company, J. P. Bemberg and Asahi Kasei—formerly Nippon Chisso Hiryo—implemented the cuprammonium rayon technology and formed a capital tie-up.

The first step toward kicking off the sales of Bemberg™ in Japan was the establishment of Japan Bemberg Fiber by Shitagau Noguchi. Koichi Katagiri, eventually the Vice President of Asahi Kasei, left Nippon Chisso Hiryo and transferred to Japan Bemberg Fiber along with 19 others. Later on, Shigeyuki Hamada, eventually president of Asahi Kasei, also joined from Asahi Fabric along with two others. The fact that such eminent individuals were deployed shows their commitment.

Led by this team, they worked toward establishing Japan’s cutting-edge cuprammonium rayon technology under the guidance of a German engineer, and finally, the sales of Bemberg™ started.

However, Bemberg™ was not selling well at all during its first year on the market. During the difficult time when rayon reached its lowest-ever price, dropping below 100 yen, there is no doubt it was difficult to promote it as a new product.

Moreover, there were other issues on the company’s side, such as unstable quality where the material’s texture was bad and stiff and the thread is not uniform. They were facing numerous problems, such as the major incident at the factory that continued for a few months where foreign substances would drop into the spinning machine and get mixed in.To overcome this situation, at the Nobeoka Plant, they worked on improving the quality by using a special garment washing method during the refining process to prevent the skein from being messy and improve the texture of the material, which they received many complaints about.

In addition, Bemberg™ did not give great results when using the same dyeing method as that used for the conventional viscose rayon, so they wrote a note with special dyeing methods on each product’s box, providing the dyeing factories with thorough instructions. They visited the regions where the notes were not effective. Since it was exported textile, they even visited factories in Tianjin and Shandong in China.

Thanks to their efforts, their sales improved after over a year of its sales. Bemberg™ started gaining more attention, giving processing companies the momentum to create products that leverage the features of Bemberg™, such as its elegant and soft texture, durability, and ease of washing.

Around 1933, most of Japan’s main silk and rayon fabric production areas started using Bemberg™. Jumping on the trend, an increasing number of factories was established one after another, and in 1935, the Nobeoka Plant became the world’s largest Bemberg™ plant. In terms of equipment, their capabilities were unparalleled. They worked on their own initiative to improve their technical side to the extent that they partially surpassed Germany.

Knowing that they were learning the techniques under the guidance of a German engineer just a few years before, it is not difficult to imagine their immense hard work.

After that, they expanded steadily as their fabric was used in the lining of suits and traditional overseas costumes, such as Indian sarees, and is currently used in Uniqlo’s AIRism as mentioned at the beginning of the article.

The use of this fabric was not only limited to apparel applications. In the 1980s, the Fiber R&D Department started developing medical tools using Bemberg™ (Cupra hollow fiber). In 1987, the company launched the BMM (Bemberg™ Microporous Membrane) project and worked on using the fabric for more applications.

As a result, in 1990, they succeeded in launching Planova™, which aims to remove the AIDS virus as well as the hepatitis B and C viruses from blood plasma. After that, they established the Planova Development Department and started commercialization activities. Currently, Planova is one of Asahi Kasei’s main medical businesses.

Being solely focused on the development of new applications, Bemberg™ celebrated its 90th anniversary one year ago in 2021 while Asahi Kasei was celebrating its 100th anniversary. Currently, the other manufacturers and factories have closed due to the competition in the fiber business, making Asahi Kasei the only manufacturer of Bemberg™ in the world.

While repeatedly developing new applications and innovating technology, Bemberg™ has been contributing to people’s lives across the globe as a global one-of-a-kind business that meets society’s needs. Moreover, the technology they have been innovating expanded to medical applications, contributing to saving lives around the world through the anti-virus field. Perhaps the 100th anniversary awaiting 9 years from now is just a passing point for the inherited business, Bemberg™, which shares the same philosophy with Asahi Kasei.

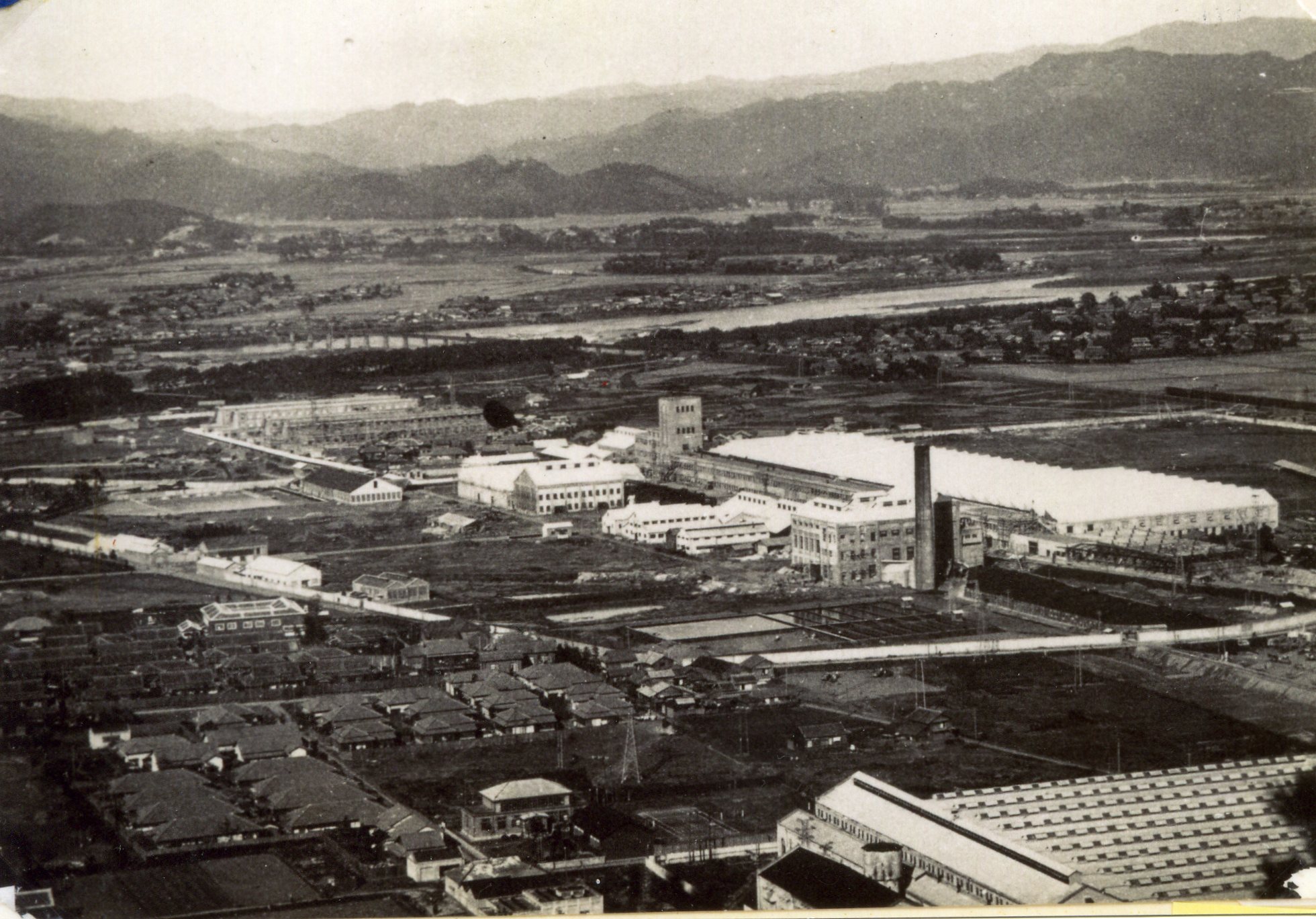

The completion of the first construction of Japan Bemberg Fiber, Nobeoka Plant (1931)

The completion of the first construction of Japan Bemberg Fiber, Nobeoka Plant (1931)

The completed company dormitory (Japan Bemberg Fiber, 1930)

The completed company dormitory (Japan Bemberg Fiber, 1930)

The completed dormitory for female plant workers (Japan Bemberg Fiber, 1931)

The completed dormitory for female plant workers (Japan Bemberg Fiber, 1931)