100 Stories1934 Overcoming More Than a Few Tight Situations. Trends in nitrocellulose

Asahi Kasei's nitrocellulose is the oldest product in the history of the company. Once the company was the number one in the industry and the front runner in the field.

Nobeoka, the birthplace of Asahi Kasei, is an important place in the history of the Japanese chemical industry. The ammonia produced in Nobeoka was utilized as a raw material for other new products, from nitric acid to gunpowder, nitrocellulose cotton and Bemberg™. The businesses were formed one after another.

Nitrocellulose production began in 1934, using nitric acid, a derivative of ammonia, as the raw material. Using this nitrocellulose cotton, we developed Chissoloid™, a celluloid that does not use camphor, a natural plasticizer.

Chissoloid™ was a turning point in the nitrocellulose business, but the road to completion was very difficult.

The production of celluloid depended primarily on machinery and the availability of camphor, which is used as a plasticizer sold exclusively by the government. Nippon Chisso Kayaku was eager to get machinery that would require a lot of time and effort to obtain, and was optimistic about the availability of camphor.

In Japan, camphor was not only sold domestically but also exported to other countries around the world, and it was thought that there would be no problem in processing it for celluloid production. However, negotiations ran into a deadlock when existing celluloid manufacturers, who were receiving camphor rations, opposed the entry of other companies.

President Shitagau Noguchi then conceived the idea of establishing a company in Taiwan, where camphor was produced, but even there, the Government-General of Taiwan refused to allow the company to enter the market. Mass production of celluloid without camphor was not yet developed in Japan, and the situation seemed hopeless.

Nevertheless, the company did not give up, and as a result of repeated research, succeeded in developing the prospect of using a synthetic plasticizer. The production system of Chissoloid™ was the first of its kind in Japan, and took a lot of hard work.

Production volume steadily increased along with nitrocellulose for lacquer and nitrocellulose for leather, which began to be produced at the same time, but the momentum of nitrocellulose declined after peaking around the 1940s. Nitric acid, which is also a raw material for the production of gunpowder, was in short supply as military demand expanded with the start of the Pacific War, so the use of nitrocellulose for applications dependent on civilian demand was severely restricted, forcing a reduction in production.

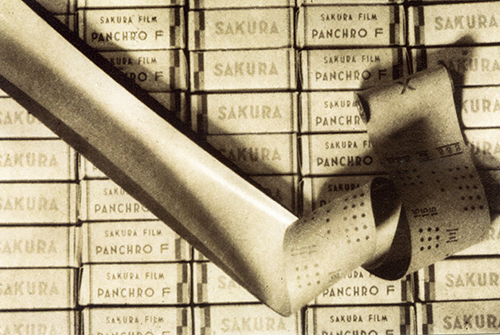

After the war, in the 1950s, as Japan's economy recovered and people's lives became more stable, the market for photographic film applications grew. 1953–54 ushered in the camera boom era and demand was at its highest level, but the flammability of the film became a problem, so it was replaced by nonflammable film that did not use nitrocellulose.

Nitrocellulose cotton has long been ideal for lacquers and other paints because of its extremely good pigment dispersibility, but demand gradually declined as lacquers yellowed over time and urethane paints took over the market.

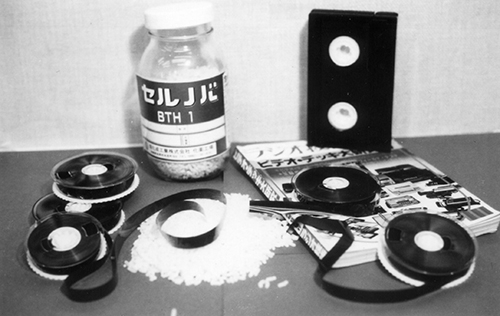

In such dire straits, we groped for a solution, and eventually came upon one. In just four years since it was first produced as a raw material for videotape, Cellnova emerged as a powerful strategic product in Asahi Kasei's decades-old nitrocellulose business.

The project leader at the time said, “At the start of this development, we could not have predicted the current prosperity. However, if it takes five years for development, I think we can get good results by studying how society will have changed in five years, and then going forward with that as our belief, on top of strenuous efforts.”

Even after sales of nitrocellulose peaked in the late 1980s and began to decline, Cellnova showed long-lasting success, including growth in applications for magnetic tape binders. Thereafter, nitrocellulose research continued at the Asahi Kasei Polymer Research Institute, but the decision to withdraw from the industry was made in 2003, and the business was transferred to a French company.

Sakura film

Sakura film

Videotape using Cellnova

Videotape using Cellnova