After nylon, we established a Construction Materials Division in April 1963 and a Synthetic Rubber Division the following month. As we moved to commercialize these two areas with high potential, both projects faced difficulties.

Construction materials especially left us at a loss since we couldn’t apply Asahi Kasei’s existing technologies. The research staff looked everywhere for a partner who could provide technology. Eventually we decided to adopt SILIKALTSIIT™ autoclaved lightweight concrete from the Soviet Union. We started production in November 1963, but it was a complete failure.

Silikaltsiit was strong, lighter than ordinary concrete, and could be made from regular sand, but we couldn’t overcome the cultural difference regarding cost consciousness. In the Soviet Union, they made construction materials that were large and strong without concern for the cost.

Despite its good qualities, this material was unsuitable for homes in Japan where greater precision is required. The engineers did a lot of research, but couldn’t get the cost down enough to make it profitable. Our total losses reached almost 3 billion yen.

We had to give up on Silikaltsiit. This experience taught me just how important it is to do enough research in advance when entering a new field.

But that didn’t mean we were giving up on construction materials altogether. We heard from an employee stationed in West Germany that the lightweight aerated concrete of Hebel Guston was extremely good. This time, we conducted extensive research before concluding an agreement to license the technology from them. Mr. Kuroda did most of the work for this project. It was memorable that even he, who always exuded confidence, shed a tear when signing the agreement saying “This is going to last.”

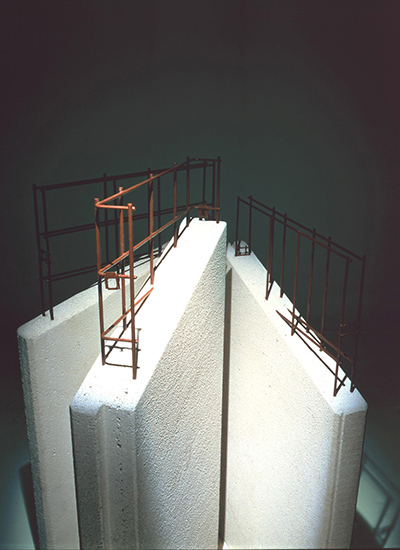

We started making “Hebel” in August 1968. It was one-quarter the weight of ordinary concrete and had excellent thermal insulation and flame resistance. It found widespread use in buildings, factories, and ordinary homes, and quickly grew to be a major pillar of business.

We also leveraged this material to expand into housing, and started sales under the “Hebel Haus” brand in September 1972. Sales from housing and construction materials have grown to 130 billion yen, making it our biggest source of earnings.

Meanwhile, we licensed synthetic rubber technology from the Firestone Tire and Rubber Company in the United States, starting production in November 1964. It wasn’t easy for us, since the Japanese synthetic rubber market was dominated by Japan Synthetic Rubber, which was backed by the government, and Zeon Corporation, part of the Furukawa Group.

The two companies were making styrene-butadiene rubber, which has lower heat dissipation and wears more quickly than natural rubber. The polybutadiene rubber developed by Firestone had the advantages better abrasion resistance, less heat generation, and aging resistance, as well as being economical.

But we had a hard time convincing users. We had to quickly prove the superiority of our product, so had a car with polybutadiene rubber tires drive nonstop back and forth between Tokyo and Osaka. They only stopped to switch drivers in Tokyo and then went straight back. We showed the data to tire makers.

We also had elementary-school students and station lunchbox vendors wear shoes with soles made of our rubber. Elementary-school students run around a lot and lunchbox vendors walk around the station carrying lunchboxes, so we quickly gathered a lot of data.

I even went to visit potential users around Japan myself. I privately purchased 50,000 shares in Yokohama Rubber Co., Ltd., to show my sincerity, and they signed a purchase agreement for our synthetic rubber. I repeatedly called on Bridgestone Corporation President Shojiro Ishibashi, who asked me, “Does the President do the selling at your company?”

Thanks to such efforts, demand for our synthetic rubber gradually increased from the mid-1960s. At last we were able to say “the three novelties” had succeeded.

In each case, it was really the section chiefs and assistant managers who provided the most valuable support. There were some outstanding engineers who advocated for the earlier commercialization of nylon, and reluctantly accepted the decision not to do so until later. But they ended up being the ones who made it succeed when we did decide to commercialize. There’s always a lot of work by people behind the scenes for any business to succeed.

Hebel™ Autoclaved aerated concrete (AAC)

Hebel™ Autoclaved aerated concrete (AAC)

polybutadiene synthetic rubber

polybutadiene synthetic rubber