Asahi Kasei starts construction of alkaline water electrolysis pilot test plant for hydrogen production

November 7, 2022

Asahi Kasei Corp.

Asahi Kasei has started the construction of an alkaline water electrolysis pilot test plant for hydrogen production at its Kawasaki Works. Construction and operation of the plant is supported by the “Green Innovation Fund1” of Japan’s New Energy and Industrial Technology Development Organization (“NEDO”).

Background

Hydrogen-related business is one of Asahi Kasei's "10 Growth Gears" (GG10), businesses to lead the next phase of growth in fields of focus as part of its medium-term management plan 2024 focused on the theme “Be a Trailblazer.” Asahi Kasei is currently advancing its hydrogen-related business centered on the alkaline water electrolysis system for hydrogen production developed utilizing its experience and expertise gained with the membrane process for chlor-alkali electrolysis.

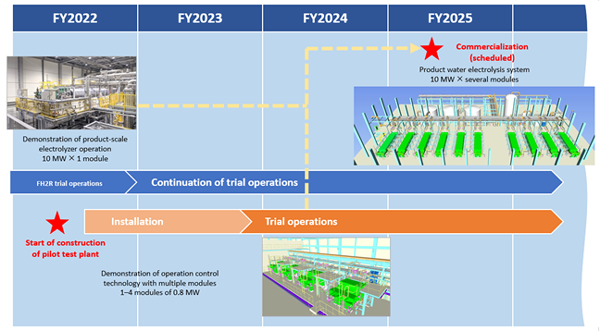

Asahi Kasei installed a large 10 MW-scale alkaline water electrolysis system at the Fukushima Hydrogen Energy Research Field (FH2R) as part of a NEDO project,2 and performed several trial operations3 since 2020. Based on the technological achievements obtained at FH2R, Asahi Kasei plans to commercialize a larger-scale alkaline water electrolysis system comprising multiple 10 MW modules4 by 2025.

Objectives

Asahi Kasei believes that it will be necessary to further increase the scale of electrolysis equipment in order to meet the great demand for hydrogen expected around the world. At the same time, Asahi Kasei is aware of the challenges in developing technology for highly reliable products that are compatible with fluctuating electrical power generated from renewable energy.

To solve these issues, Asahi Kasei decided to introduce a pilot plant comprising several electrolyzer modules to perform various trial operations regarding responsiveness to power fluctuation, long-term durability, etc. Asahi Kasei expects that this will greatly accelerate the development of its water electrolysis technology.

Features of the pilot test plant

Changeable configuration with 1–4 water electrolysis modules of 0.8 MW

As the system comprises multiple modules, the behavior of equipment under various conditions can be replicated, such as the case where one module malfunctions during operation, or the case of low output operation at night. This facilitates verification and improvement of apparatus design, operation methods, and control technology.

Equipment designed to replicate fluctuating output of renewable energy

As renewable energy sources such as solar and wind provide unstable power output, water electrolysis equipment needs to be highly responsive to fluctuations. As the equipment is designed to simulate such fluctuations, it enables verification of compatibility with renewable energy and coordination with the power system.

Illustration of water electrolysis pilot test plant

Illustration of water electrolysis pilot test plant

Moving forward

The groundbreaking ceremony was held at the end of October 2022. Start of operation is targeted in early 2024 following construction work, equipment installation, and trial operation.

Positioning of water electrolysis pilot test plant

Positioning of water electrolysis pilot test plant

Nobuko Uetake, Senior General Manager of Asahi Kasei's Green Solution Project, at the groundbreaking ceremony for the water electrolysis pilot test plant

Nobuko Uetake, Senior General Manager of Asahi Kasei's Green Solution Project, at the groundbreaking ceremony for the water electrolysis pilot test plant

- 1NEDO project name: “Technology development for increasing the size of water electrolysers, and Power-to-X large-scale demonstrations/Large-scale Alkaline Water Electrolysis System Development and Green Chemical Plant Demonstration” under the “Green Innovation Fund /Hydrogen Production by Water Electrolysis Using Renewable Energy”

Press release: "Start of green chemical plant demonstration project utilizing large-scale hydrogen production system" - 2NEDO project name: "Hydrogen social construction technical development project/Hydrogen energy system technical development/Technical development concerning business model construction and the large-scale actual proof of a re-energy use hydrogen system"

- 3Press release: "Asahi Kasei’s electrolysis system starts world’s largest-scale hydrogen supply operation at the Fukushima Hydrogen Energy Research Field in Namie"

- 4A module is a unit composed of a water electrolyzer and minimum peripheral apparatus. For commercial products, each system will have several 10 MW-scale modules according to customers' output requirements while costs are reduced by sharing peripheral apparatus outside the modules.