Process Safety

Policy

As part of its Group Philosophy, the Group Mission of the Asahi Kasei Group is to contribute to life and living for people around the world.

Based on this Group Mission, the Asahi Kasei Group ESH & QA and Health & Productivity Management Policy, revised on July 11, 2022, states, "the Asahi Kasei Group gives the utmost consideration to health maintenance, operational safety, occupational health and safety, quality assurance, and environmental protection throughout the product lifecycle from R&D to disposal as preeminent management tasks in all operations." Furthermore, as a specific matter regarding ESH, the policy states "we strive for stable and safe operation while preventing workplace accidents and securing the safety of personnel and members of the community."

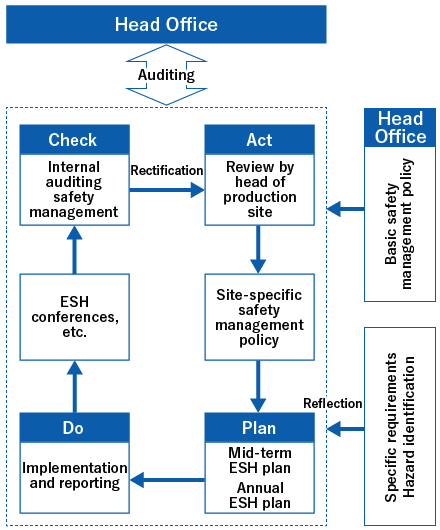

PDCA cycle for safety management

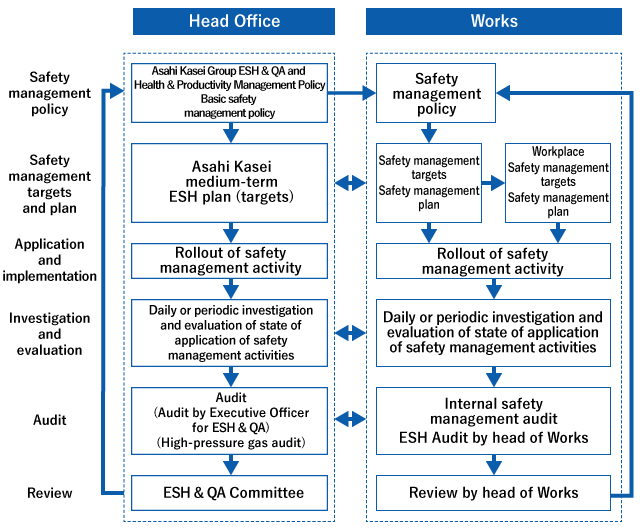

PDCA cycle for safety management Process safety management system

Process safety management system

Safety management for high pressure gas

At the Mizushima Works and Kawasaki Works, we have received certification for self-inspection for high-pressure gas safety from Japan's Ministry of Economy, Trade and Industry. Accordingly, we perform our own "certified safety" and "conformity inspections" for equipment as part of the ongoing effort to maintain stable and safe operation, and we ensure the safety of the applicable facilities.

Concrete activities are based on the High Pressure Gas Safety Act and are specified in the High Pressure Gas Certification Safety and Completion Test Regulations approved by the President of Asahi Kasei.

| High Pressure Gas Safety Controller | Asahi Kasei Corp. President |

|---|---|

| High Pressure Gas Process Safety Division General Manager | Asahi Kasei Corp. Director |

| High Pressure Gas Process Safety Management Department General Manager | Asahi Kasei Corp. Senior General Manager of Corporate ESH |

We held the High Pressure Gas Process Safety Measures Promotion Conference (chaired by the Asahi Kasei Corp. Senior General Manager of Corporate ESH who is head of the High Pressure Gas Process Safety Management Department) four times (July and October 2022 and January and April 2023) with the relevant parties from head office, the Mizushima Works, and the Kawasaki Works in order to exchange information in a timely manner and implement the PDCA (plan-do-check-act) cycle. Furthermore, the High Pressure Gas Process Safety Measures Meeting, chaired by the High Pressure Gas Process Safety Division General Manager (Asahi Kasei Corp. Director commissioned by the President), was held once (July 2022) to check on the status of process safety at the Mizushima Works and Kawasaki Works. In addition, the on-site patrol by the High Pressure Gas Process Safety Division General Manager was conducted in December 2021 at the Kawasaki Works. For the past two years, both the Mizushima Works and Kawasaki Works have recognized continuing operations as a key issue, and took thorough measures to prevent COVID-19 infections and secure the availability of personnel, ensuring that operations did not have to be suspended due to infections.

The Mizushima Works was awarded super certification (Specified Certified Operator), which necessitates a higher level of high-pressure gas safety management, in September 2021 when the high-pressure gas safety certification was renewed. The Kawasaki Works also applied for and obtained ordinary certification during the renewal audit in August 2022. Along with other sites that have not yet acquired the certification for self-inspection, we will strive for more advanced high-pressure gas safety management.

Basic Policy for High Pressure Gas Safety

- Safety is an important fundamental of management, and all of our business activities depend on safety.

- Each one of our employees is responsible for safety, and safety is ensured by all employees together.

- We apply a PDCA (plan-do-check-act) cycle to continuously improve the level of safety.

- Measures to assess risks, and to eliminate and mitigate them, are persistent and ongoing.

Process safety management

In fiscal 2022, 16 safety-related accidents occurred, including at domestic and overseas affiliated companies.

[Number of safety-related accidents in fiscal 2022]

- Number of serious industrial accidents: 0 (accident intensity of 18 points or more, or accident resulting in death)

- Number of industrial accidents: 2 (accident intensity of 3 points or more but less than 18 points)

- Number of minor industrial accidents: 14 (accident intensity of less than 3 points)

Note: Classification by accident intensity is based on the standards of the Japan Petrochemical Industry Association (CCPS).

In fiscal 2022, there were no serious industrial accidents, but there were two industrial accidents. The first was in April 2022, when a fire occurred at the Bemberg Plant and lasted for 8 1/2 hours before being extinguished. Along with the semiconductor plant fire that occurred in October 2020 (which lasted for 64 hours before being extinguished), there were issues with fire prevention measures at indoor plants, so we have begun new activities for prevention. The second was in September 2022, when a fire occurred at the Saran Intermediate Manufacturing Section due to polymer burning inside a dryer.

There were also 14 minor industrial incidents which occurred such as small fires, smoldering, and small leaks of hazardous materials on the premises, but thorough primary measures on site prevented damage from spreading. We will continue to strengthen our efforts to reduce the severity and number of industrial accidents going forward.

Improving fire prevention measures by establishing standards for installing fire prevention equipment in areas at high-risk of indoor fire

Regarding the semiconductor factory fire in October 2020, we established an accident investigation committee and released a fire accident investigation report in September 2021. Since the fire occurred in a clean room, we investigated all 216 of our clean rooms in order to identify measures to prevent recurrence, and conducted on-site inspections of 14 domestic clean rooms and held an interview regarding one overseas clean room. We found some cases where early detection of fires would be difficult, and some cases where effective fire extinguishing equipment was already in place. Furthermore, the subsequent fire situation at the Bemberg Plant showed that once flammable plastics and cardboard catch fire, it is difficult to extinguish the fire in an indoor plant, so fire prevention measures were looked at that focused not only on clean rooms but also on indoor fires in general.

| Semiconductor plant fire (October 2020) |

Bemberg plant fire (April 2022) |

|

|---|---|---|

| Arrangement of people | Three-shift workplace, but not manned all the time | Three-shift workplace, but not manned all the time |

| Equipment where fire occurred | Flammable plastic inside machine | Contains flammable materials such as cardboard and paper tubes |

| Earliest detection | Because it was a clean room, smoke was being purified from the air, which enabled the fire to build up before the smoke detector activated | A heat alarm sounded, but the fire had already spread by the time someone got to the scene |

| Initial extinguishing | The first person on scene thought it couldn't be put out with a fire extinguisher | Attempted to put out fire with extinguisher, but the flames were too high to put out |

| Fire department response | Difficult to go inside as the space is almost completely sealed | Took time to shut down utilities, spraying water only began after 1 1/2 hours |

On the other hand, we were also able to obtain advanced knowledge about fire prevention equipment from outside experts. A system that can detect fires early even in clean rooms where smoke is purified from the air has already been put into practical use, and we have also confirmed examples of using this system in the company to enable the quick extinguishment of fires. We were also able to confirm examples of the installation in the company of fire extinguishing equipment to prevent the spread of fire after it breaks out. In order to widely deploy these throughout the company, we established standards in March 2023 for installing fire prevention equipment in areas at high-risk of indoor fire. We will implement improvements in the future, including putting fire extinguishing equipment in areas that are at high-risk of fire, such as in places where cardboard boxes for product shipment are stored. We will also increase both the quality and frequency of disaster prevention training, and revise the emergency response plan submitted to the fire department in order to prevent fires from occurring and prevent them from spreading.

Drenchers which prevent a fire from spreading

Drenchers which prevent a fire from spreading

Activities to pass on operational safety technology

Details of initiatives under activities to pass on process safety technology

To achieve safe operations, it is essential to perform sound plant maintenance, and to operate facilities in a safe and stable manner. The Asahi Kasei Group carries out process safety risk assessments during plant construction and puts in place controls to prevent fires and explosions after the start of operation. We periodically inspect safety valves and interlock functions, properly maintain aging parts, and repeatedly review facilities and processes based on case studies of accidents both inside and outside the company.

In particular, in response to the so-called three major accidents that occurred outside the company in 2011, we began activities to pass on operational safety technology in 2013. These activities involved identifying hazards in chemical plants, confirming preventive measures that may manifest as risks, and passing on the details.

The activities consist of the following four steps:

- Step 1: Identification of hazard sources and assessment of hazard risks

- Step 2: Creation of technology transfer materials and succession of executive changes using summary materials

- Step 3: Training operators to use troubleshooting manuals, factor analysis, etc.

- Step 4: Training of operators with ability to apply knowledge to work through troubleshooting drills

First, in Step 1, we rank the hazard sources identified from brainstorming and by accidents that occurred in the past. In a system where a runaway reaction occurs due to some deviation, if safety devices such as interlocks and safety valves do not function, or if the container exceeds the design pressure and there is a possibility of rupture, it is defined as Hazard Rank A. Naturally, we maintain a low risk rank by implementing multiple operational controls that do not cause deviations and by maintaining and managing safety devices. In addition to these abnormal reactions, we will also consider abnormalities, such as suspension of service, contamination, and expiration of polymerization inhibitor, and how to deal with them.

In addition, Step 4 involves training to ensure that operators working in shifts can correctly respond to expected abnormalities (training to determine the cause of abnormalities, respond, and prevent them from spreading). The individual skills of the trainees are then assessed to ensure that they are acting in the correct manner, and retraining is conducted until their skills reach the level required for their role.

Here we will look at some example activities carried out in the manufacturing section. Many talented and experienced operators in this manufacturing section have retired, with most of them replaced by younger operators with little experience working in a chemical plant. In addition to teaching the new personnel how to operate, we make use of the safety and disaster prevention technology transfer activities so that they can appreciate the underlying manufacturing technology as well. The operators are educated on Steps 1 and 2 above using technical materials, etc., and then trained so that they can master Steps 3 and 4.

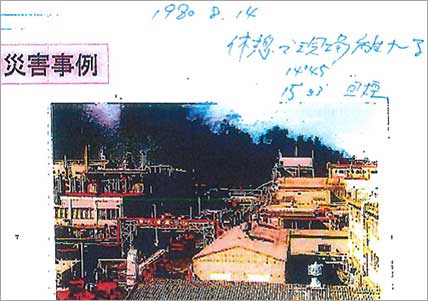

Here is an example from the documentation passed on of a fire caused by the materials handled in this manufacturing section that occurred in 1980. At the time, the manufacturing department regularly collected and disposed of a fine layer of dust that had accumulated on the roof of the factory. However, one of the plastic bags containing the dust that had been collected during a sunny summer’s day spontaneously ignited, and the fire spread to the rest of the plastic bags containing the dust. After this accident, dust collection equipment was improved so that dust was no longer discharged onto the roof, but the potential danger inherent to the substance remains unchanged. Therefore, this activity summarizes the multiple countermeasures that were identified and implemented at the time as the cause of the fire, and provides education on the implications of the work. This activity not only prevents recurrence, but also prevents unintentional failures in change control.

Excerpt from materials related to past accidents at the Kawasaki Works

Excerpt from materials related to past accidents at the Kawasaki Works

Kayaku Japan Co., Ltd. Tohmi Plant explosion

In March 2022, an explosion occurred at the Tohmi Plant of Kayaku Japan Co., Ltd., resulting in a very tragic accident that killed one person who was assigned to manufacturing work. Kayaku Japan Co., Ltd. is a company in which Nippon Kayaku Co., Ltd. and Asahi Kasei have invested 50% each. Kayaku Japan Co., Ltd. has established an accident investigation committee with third party outside experts to examine and investigate the cause of the accident. In January 2023, a summary of the investigation results was released.

According to the published report, the explosion occurred in the cleaning room, which is the next step in the process after the nitrification room where nitroglycerin is synthesized. The above-mentioned safety and disaster prevention technology transfer activities were also carried out at Kayaku Japan Co., Ltd. Tohmi Plant, and were finalized in 2016. The applicable facility was a nitrification room where an accident had occurred in the past, but there were no documents regarding the cleaning room or other areas.

However, the nitrification, cleaning, and compounding rooms all handle the extremely hazardous nitroglycerin, so it is possible that they were not fully aware of the nature of this activity. It is also possible that Corporate ESH of Asahi Kasei, which should be inspecting the plant as a third party, did not identify the inherent dangers of the substance and did not give instructions to evaluate the next process step.

We will reflect on these deficiencies in our safety and disaster prevention technology transfer activities, which we began reinforcing in fiscal 2022, and will utilize them in various activities related to safety and disaster prevention.

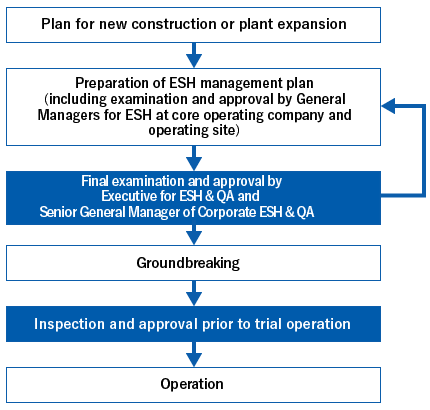

Pre-screening when investing in equipment

We perform process safety assessments before plant construction to ensure safety, not only when establishing new plants or expanding plants but also when modifying or dismantling plants. Based on our pre-inspection standards for capital investment, we conduct pre-installation safety inspections and pre-trial safety inspections before starting actual operation to confirm safety of new or modified equipment of a certain size or larger. The inspection system is applied not only in Japan, but also outside of Japan.

Safety assessment is performed as part of the pre-investment inspection. Ranks are assigned based on the degree of hazard, with methods such as HAZOP* utilized in the risk assessment of high risk facilities.

- *HAZOP

“Hazard and Operability Study”

A method of identifying causes behind occurrences and countermeasures based on assumptions due to deviations from design points. This highly exhaustive method is widely utilized throughout the process industries.

System for inspection prior to capital investment

System for inspection prior to capital investment

Measures for safe and stable production at plants

Given our diverse range of operations that include the Material, Homes, and Health Care business sectors, the Asahi Kasei Group has plants with a wide variety of different characteristics. No single approach to safety would be appropriate for all plants.

We employ a systematic process to tailor the safety effort to each plant's specific requirements, including the use of the PDCA cycle. One characteristic of this process is the formulation of separate maintenance standards for each individual unit of equipment to ensure the appropriateness of the method and period of maintenance.

In addition, measures that span across the Asahi Kasei Group include a Maintenance Personnel Committee and group-wide plant engineering council with 4 specialist panels: Formulation of optimum systematic maintenance programs, establishment of standards and criteria, formulation of training systems for maintenance engineers, and sharing engineering information. We will ensure safe and stable production at our plants through these maintenance activities.

Training for maintenance

We believe that maintenance means creating the condition of equipment necessary to accomplish production objectives. Although we use a PDCA cycle for the planned maintenance system, people are the most fundamental element. It is vital for each individual to gain the essential technical knowledge and contribute to the strength of the team.

The Asahi Kasei Group’s maintenance technicians should have the ability to carry out planned maintenance, to predict hazards, and to make improvements rather being purely repair personnel who fix malfunctioning machinery and return it to its original state. To develop such maintenance technicians, we clarified the training principles for maintenance technicians, formulated a training curriculum for each individual based on these principles from fiscal 2009, and applied the PDCA cycle for education and training based on the curriculum for all maintenance technicians.

Training for process safety

At our petrochemical sites in Mizushima and Kawasaki, the Asahi Operation Academy (AOA) serves as the training center to cultivate the skills necessary to conduct production activities at petrochemical plants. AOA teaches the principles and structures of equipment, heightening the ability to identify the cause of equipment failure and to respond appropriately. Miniature plants and simulators are used at AOA to provide hands-on experience with controls and instrumentation. Operators thereby gain the technical skills and practical understanding of chemical engineering necessary for safe and reliable plant operation, with the ability to respond appropriately in the event of any abnormality.

In conjunction, we provide education on human behavioral characteristics and accident case studies in order to instill greater sensitivity for safety among employees and obtain strict compliance to safety rules to avoid dangers. We carry out safety training exercises in which employees are given simulated experience of workplace dangers including being caught in/between machinery, contacting hazardous liquids, tripping and falling on the same level, suffering a burn, falling from height, etc.

From fiscal 2019, we began incorporating VR experiences into our basic engineering education and safety training curriculum, and we are working to enhance training to improve risk sensitivity in equipment handling and operation.

| Regularly conducted training | Basic technology courses (machinery, instruments, electricity, and chemical engineering) Safety experience courses (being caught in/between machinery, contacting hazardous liquids, suffering a burn, stumbling, tumbling or falling, getting scalded, etc.) Job level-based courses (problem-solving training, etc.) |

|---|---|

| Training target | Manufacturing operators and facility management personnel |

Emergency response

A comprehensive set of internal regulations guides the proper response to any industrial accidents or natural disasters which may occur.

The smooth operation of the emergency response system ensures that personal safety is secured, that effects of the situation are prevented from spreading to surrounding areas, and that damage is held to a minimum, through close communication between the plants, regional management, and the head office. The plants prepare annual plans for periodic training drills, and perform drills in coordination with the head office.

In Fuji, a firefighting competition sponsored by the Fuji City Fire Association was held for the first time in three years now that the pandemic has ended. Five teams from the Fuji branch participated with the Asahi Kasei Homes team taking third place in the indoor fire hydrant category. We will continue to discuss with each site how to strengthen the planning and implementation of effective disaster prevention drills.

The Asahi Kasei Homes team from the Fuji Branch taking part in the firefighting competition hosted by the Fuji City Fire Association (September 14, 2022)

Transportation and Distribution Safety

To prevent transportation and distribution accidents related to dangerous goods, such as hazardous materials, poisonous substances, and high-pressure gases, and to further improve the quality of our logistics, the Asahi Kasei Group is engaged in various safety activities such as logistic safety and quality conventions, safety meetings, safety inspections, and product handling education together with logistics providers contracted for the storage, handling, and transportation of products.

In addition to a logistics safety quality conference, in which logistics companies were brought together both online and face-to-face, together with senior management from Asahi Kasei to raise awareness around safety, a safety conference was held in fiscal 2022 attended by many people involved with different products.

Main activities in fiscal 2022

- Logistics safety and quality symposium: 50 companies

- Safety meeting for dangerous goods (held twice per year): 35 companies

- Safety meeting for resin products: 11 companies

- Safety meeting for photosensitive dry films: 3 companies

- Logistics safety inspection: 43 companies

- Product handling training: 21 items, cumulative 82 companies

In addition, we have introduced HAZMATers (Hazardous Materials Emergency Response Service), provided by the Maritime Disaster Prevention Center, to further strengthen our ability to respond to emergencies. The engagement of HAZMATers makes a highly specialized emergency response available 24 hours a day, 365 days a year, ensuring swift action to prevent the spread of damage if an accident occurs.

HAZMAT emergency dispatch vehicles

HAZMAT emergency dispatch vehicles

[Number of logistics accidents in fiscal 2022]

| Target | Results | |

|---|---|---|

| Serious logistics accidents* | 0 | 0 |

| Logistics accidents** | 0 | 1 |

(Excluding some affiliates such as Asahi Kasei Homes)

In a logistics accident that occurred in fiscal 2022, a worker's wrist got caught and was fractured during unloading. Corrective measures are being taken to prevent this from happening again.

- Definition of accidents

- * Serious logistics accident: (1) One or more dead or seriously injured, (2) 100 million yen or more in damages, or (3) Significant social impact (resident evacuation notice, etc.)

- ** Logistics accident: (1) Personal injury (other than a serious logistics accident), (2) Public response (firefighting, leak prevention, etc.), (3) Explosion, spread of fire, poisoning, or risk of such accidents, or (4) 5 million yen or more in damages