The Asahi Kasei Group's Environmental Contribution Products

Contribution to reducing greenhouse gas (GHG) emissions throughout society

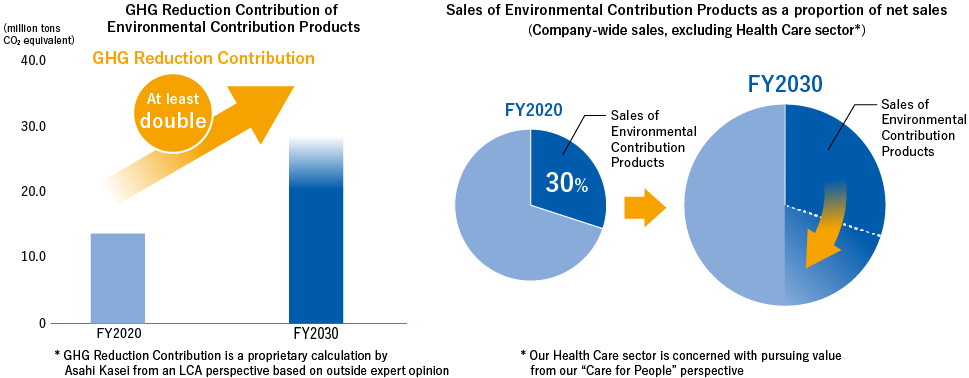

Alongside aiming to achieve decarbonization and reducing our own GHG emissions, the Asahi Kasei Group works to contribute to reducing GHG emissions throughout society. In order to realize both business growth and environmental contributions, we are working toward the following targets for 2030.

Contribution to reducing GHG emissions and increasing sales through Environmental Contribution Products

What are Environmental Contribution Products?

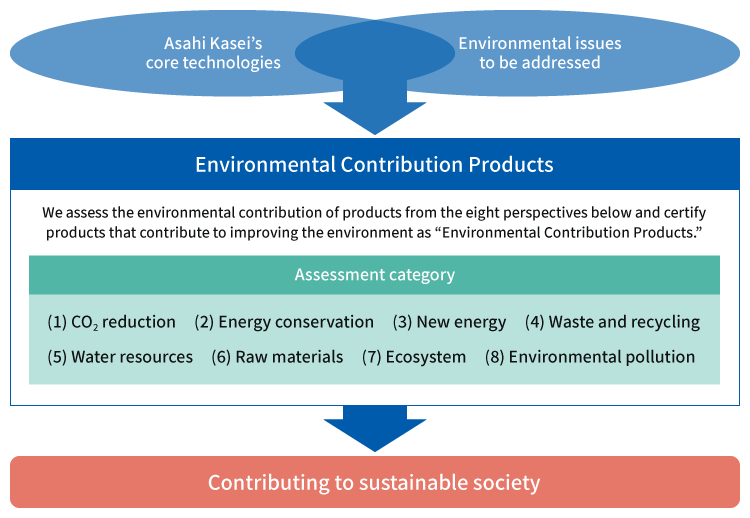

For sustainable society, we believe it is important to develop products and businesses that contribute to reducing the impact of society on the environment in addition to reducing emissions, such as greenhouse gases, at the Group’s production sites. The Asahi Kasei Group defines products that contribute to the improvement of the environment over the entire life cycle when compared with products considered to be the standard in the current market and products that contribute to the improvement of the environment when compared with our existing products as Environmental Contribution Products.

Our Environmental Contribution Products are managed under our own Guidelines for Environmental Contribution Products, which were prepared with reference to Guidelines for Assessing the Contribution of Products to Avoided Greenhouse Gas Emissions (The Institute of Life Cycle Assessment, Japan), Guideline for Calculating the Reduction in CO2 Emissions (Japan Chemical Industry Association), Guideline for Quantifying GHG Emission Reduction Contribution (Ministry of Economy, Trade and Industry), and other reference materials.

In making the abovementioned calculations, we use MiLCA, an LCA software provided by the Sustainable Management Promotion Organization (SuMPO).

What is Life Cycle Assessment (LCA)?

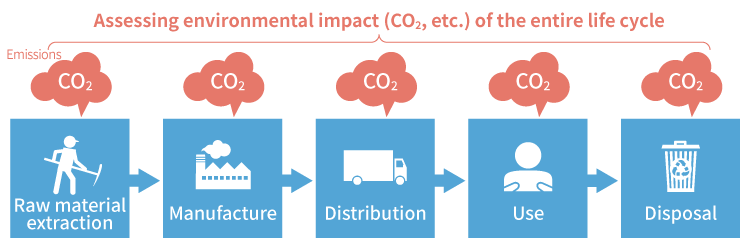

Although CO2 is generated during the manufacture of materials and intermediate products in the Asahi Kasei Group, there are also many examples of products which contribute to improving the environment by reducing environmental impact, including CO2, during use considering the entire product life cycle, such as contributions to energy conservation.

The evaluation of the environmental impact of products over their entire life cycle is Life Cycle Assessment (LCA).

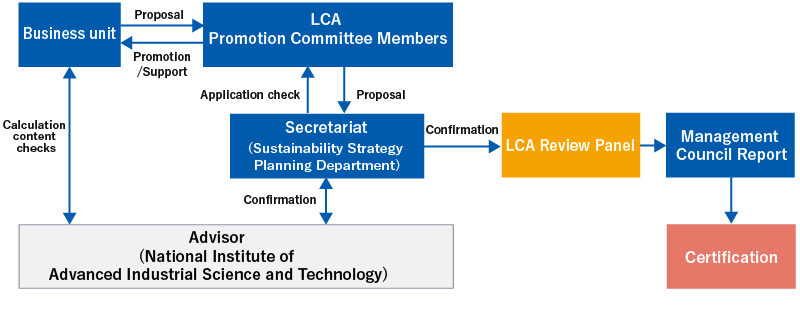

Internal Certification Process

Products proposed by strategic business units and core operating companies are internally certified as Environmental Contribution Products after receiving advice from external experts on the LCA review panel regarding the suitability of the environmental contribution calculation methodology and approach from an LCA perspective.

LCA Review Panel (held on July 4, 2023)

- Chair

- Atsushi Inaba (Chief Director of Japan Life Cycle Assessment Facilitation Centre (LCAF))

- Members

- Kensuke Kobayashi (Associate Professor, Prefectural University of Hiroshima)

Keigo Matsuda (Professor, Nagoya University)

Hiroyuki Uchida (Principal, Mizuho Research & Technologies, Ltd.)

A meeting of the LCA Review Panel

A meeting of the LCA Review Panel

At the LCA Review Panel, Asahi Kasei Group personnel in charge of each product explain the details of environmental contributions and receive comments and advice from outside experts on the suitability of the establishment of baselines and our approach to environmental contribution.

Description of Environmental Contribution Products

Contributes to resource and energy conservation at the product use stage

| Product name | Reason for certification |

|---|---|

Lithium-ion battery (LIB) Separators |

The separator is one of the four main components (cathode, anode, electrolyte, and separator) that make up the batteries (LIBs) for electric vehicles (EV/HEV/PHEV). As a result of their growing popularity, electric vehicles are contributing to a reduction in CO2 during driving, compared with gasoline vehicles. Improving the battery performance (extending range and ensuring safety) is essential to the popularization of electric vehicles, and Asahi Kasei’s development of separator technology is playing a part in this. |

| Caustic soda and chlorine are manufactured through the electrolysis of brine. The methods of electrolysis are the mercury process, the diaphragm process, and the ion-exchange membrane process. The ion-exchange process is a method that does not use the harmful materials mercury or asbestos. We are unique in that we manufacture and sell our own ion-exchange membranes, electrolyzers, and electrodes, and our products are widely used around the world. We have engaged in continual development to enable electrolysis using even less electricity, and our latest ion-exchange membrane grade has significantly lowered power consumption (compared with Asahi Kasei products: approximately 2% less than the current grade). | |

| This compact, highly accurate, energy-saving gas sensor can detect the concentration of CO2 in the air. Equipping this product to industrial air-conditioning systems and optimizing the amount of ventilation while monitoring the CO2 density will contribute to reductions in power consumption for air conditioning. | |

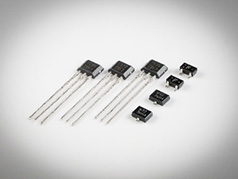

| Fan motors in home air conditioners are increasingly being replaced from non-inverter control to inverter control, which allows more precise control and helps to save energy. Hall elements and Hall ICs are used with the fan motors inside the indoor units and are essential components for realizing inverter control. Our Hall elements and Hall ICs feature high sensitivity and stable temperature characteristics. We have built a stable supply system producing approximately 1 billion units per year which are widely used around the world. With the further spread of inverter control, our Hall elements and Hall ICs can greatly contribute to energy savings and CO2 reductions. |

|

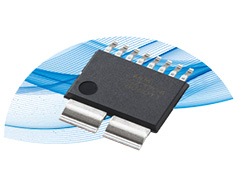

| Asahi Kasei’s current sensors generate less heat and can accurately measure large currents. Because of these unique characteristics, they are used in the compressor motors of large air conditioner outdoor units found in commercial facilities and office buildings. Used as an important component for inverter control, the current sensors reduce start-stop loss and enable operation at arbitrary speeds, helping to save energy (lower power consumption) in large air conditioners. In addition, our current sensors can detect both DC and AC currents quickly and with a high degree of accuracy. They greatly contribute not only to the smaller number of installed parts, but also to higher efficiency and improved controllability. And since they generate less heat, it means that outdoor air-con units can be made smaller. |

|

| The high-output UVC LED, which emits 265 nm deep ultraviolet (UVC), the most effective wavelength for sterilization, is installed in water servers etc. Since UVC LEDs can be instantly turned on and off, it is possible to design equipment that uses power only when sterilization is required, which helps to save energy. Recently, UVC LEDs have been used for air sterilization. In addition, unlike the conventional mercury lamps (UV lamps) used for UV sterilization, these lamps do not use mercury, which is hazardous to the environment. |

|

| This product is used as an additive for the modified asphalt used in road surfaces. This original elastomer specially designed by Asahi Kasei can improve road durability and decrease the frequency of maintenance and repairs. |

|

| S-SBR is used for the tread (the part in contact with the road) on passenger vehicle tires. Based on the development of original technology, it balances low fuel consumption and braking performance of tires at a high level, contributing to the fuel efficiency of automobiles. | |

Xyron™ lightweight resin |

Xyron™, a type of engineering plastic, is an environmentally-friendly material with non-halogen flame retardance and reduction of resin usage due to its low specific gravity. Its properties also include dimensional precision, mechanical strength, and resistance to electrolyte solution. Widely used for electric vehicle battery packs and modules, it has played a major role in the spread of electric vehicles. It is also used in high-voltage photovoltaic systems due to its excellent insulation properties. The number of modules required for high-voltage systems is reduced, which saves resources. Its low specific gravity also contributes to the reduction of CO2 emissions during transport. |

| ASACLEAN™ is a cleaning agent (purging agent) for use in plastic molding machines. At plastic molding work sites, when switching between production of different colors and resin types, it is necessary to keep the materials flowing to a certain extent, which inevitably results in loss. By using ASACLEAN™ during the production switching process, it is possible to make the switch using about 1/3 to 1/10 the amount compared to not using ASACLEAN, which contributes to conserving resources and reducing CO2 by decreasing plastic waste. |

|

| DURANOL™ is used as a raw material for high-performance polyurethane resin in applications that require durability. The water-dispersible grade developed using our proprietary technology is the world's only polycarbonatediol that can be diluted and dispersed in water without using organic solvents. Using this product allows for more use of water-based paints, etc., which contribute to reducing CO2 emissions because of less use of organic solvents. | |

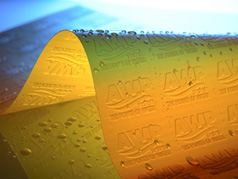

| This is a printing plate material that does not use VOC (volatile organic compound; a cause of worsening air quality) solvents during the development process. Moreover, simplifying the drying process contributes to reduced CO2 emissions by lowering energy consumption. Printing losses can also be reduced due to excellent printing quality and high productivity during printing, thereby contributing to a reduction in CO2 emissions. |

|

|

Long Life Homes and Net Zero Energy Houses: Compared with regular housing, our homes contribute to reduction of CO2 during manufacture of all components and construction by meeting the standards for Net Zero Energy Houses, which balance household energy usage at zero or lower through power generation, advanced insulation, and energy conservation, and providing Long Life Home products with a basic structural life of at least 60 years. |

|

This is a high-level insulating material, providing high insulation and maintaining its insulating properties for long periods of time. In addition, this insulation material reduces environmental impacts in a variety of ways, such as by being the first in the industry to succeed in not using any CFC or CFC substitutes as foaming gases. |

Resource and energy conservation at the product production stage

| Product name | Reason for certification |

|---|---|

| This is a process using CO2 as one of its raw materials to produce polycarbonate. We license a technology for this manufacturing process. This process utilizes CO2 released into the atmosphere by other plants as a raw material, thereby contributing to reducing CO2. The product, polycarbonate, is used for automobile headlight covers; materials for carport roofs; helmets; water bottles; and substrate layers for CDs, DVDs, and BDs; as well as exterior materials and other components for electric and electronic devices in the form of an ABS-PBT alloy. Ethylene glycol—used as a raw material for polyester fibers, PET resins, and antifreeze—is a secondary product of this process. A further strength of the process is that it manufactures its product without the use of solvents and with no inputs other than its raw materials, avoiding the environmental impacts associated with processing used solvents. |

|

| This is a process using CO2 as one of its raw materials to produce dimethyl carbonate. We license a technology for this manufacturing process. This process utilizes CO2 released into the atmosphere by other plants as a raw material, thereby contributing to reducing CO2. Demand is rising sharply for the product, dimethyl carbonate, as a raw material for polycarbonate and the electrolytes in lithium-ion batteries (LIB) for electric vehicles (EVs) and other products. Ethylene glycol—used as a raw material for polyester fibers, PET resins, and antifreeze—is a secondary product of this process. |

|

Manufacturing process for Acrylonitrile |

Acrylonitrile, which is the raw material for carbon fiber, ABS resin, and acrylic fiber, is manufactured by making propylene react with ammonia. We have continually developed catalysts that assist reactions in order to enable efficient manufacture of acrylonitrile from less raw materials. As compared to production processes using other, ordinary catalysts (in the model case), production processes using our catalysts have a low environmental impact due to the fact that these processes can (1) reduce raw material consumption, (2) reduce emissions of by-products, particularly CO2, and (3) lower CO2 emissions associated with waste processing. |

Cyclohexanol Production Process |

This production process produces cyclohexanol, an intermediate material for nylon and other chemical products, through the cyclohexane process, which Asahi Kasei were the first in the world to develop. The cyclohexene process is notable in that it generates virtually no waste and has a carbon yield of nearly 100%. Compared to conventional methods, this method uses fewer raw materials and generates less CO2 in waste treatments, which reduces the impact on the environment. |

Adipic Acid Production Process |

This process produces adipic acid, a raw material for plasticizers for polyurethane and resins. The Asahi Kasei adipic acid production process, which uses cyclohexanol produced by our cyclohexane process as a raw material, efficiently breaks down the nitrous oxide (N2O) produced by the production process and reduces GHG emissions, thereby contributing to reducing environmental impacts. |

|

Dinamica™ is an artificial suede with a 3-layer structure produced with Asahi Kasei’s proprietary manufacturing process. Having excellent texture and versatile design, it is actively being marketed both in Japan and overseas in various applications such as automotive interiors, furniture, IT accessories, clothing, and industrial materials. Dinamica™ contributes to reducing GHG emissions in two ways: 1) by increasing the usage rate of recycled polyester material, and 2) by using water-based polyurethane. |

| Ecoloop™ OPS film is used in the window film of envelopes, and has gained more than 50% of the market for windowed envelopes. Ecoloop™ uses more than 50% recycled material (recycled waste biaxially oriented polystyrene sheets) and has received Eco Mark (Japanese ecolabel) certification. This reduces the amount of virgin resin used and contributes to reducing CO2 emissions during manufacturing. |

Other Environmental Contribution Products

■Contributes to resource and energy conservation for customers