Pollution Prevention and Resource Circulation

Policy

Building a circular economy is a major plank of the Asahi Kasei Group's Global Environmental Policy, and we work to efficiently utilize resources and energy and to reduce the environmental burden throughout the entire life cycle in our business activities. In order to contribute to a circular economy, we have worked to reduce industrial waste, reduce the burden of chemical substances, prevent air and water pollution, and use resources effectively.

We are also contributing to the creation of a circular economy to achieve a carbon neutral and sustainable world as part of our focus on Care for Earth, under our Medium-term Management Plan for fiscal 2022–2024 focused on the theme "Be a Trailblazer."

Reduction of industrial waste and promotion of recycling

As well as working to reduce the amount of industrial waste through the 3Rs of reduce, reuse, and recycle, the Asahi Kasei Group is also working on renewables.

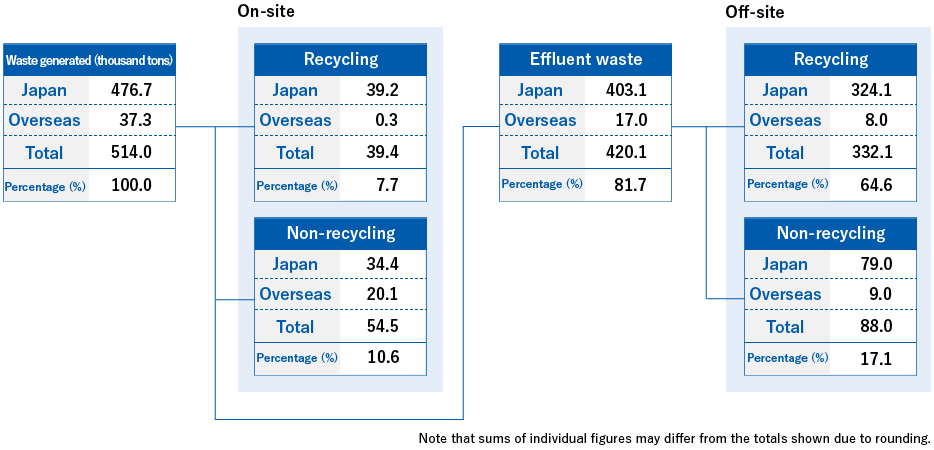

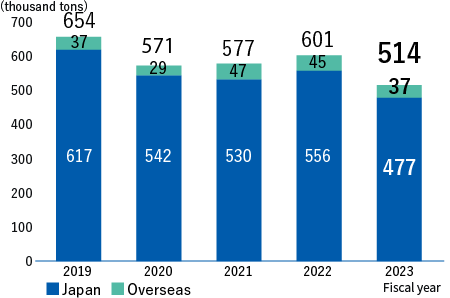

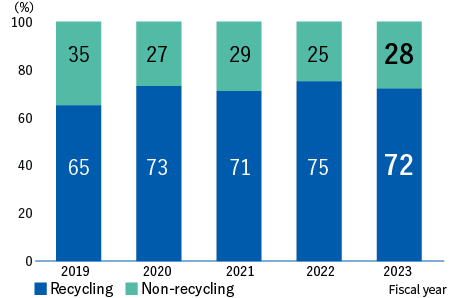

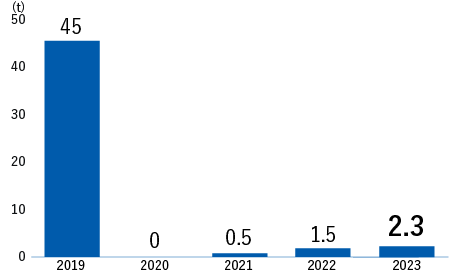

The amount of industrial waste generated by the Asahi Kasei Group (domestic and overseas) in fiscal 2022 was 600.9 thousand tons, of which 18.6 thousand tons was specially managed industrial waste. Additionally, the industrial waste recycling rate1 was 75.2%, and the non-recycling rate2 was 24.8%. So that we can continue to recycle in the future, we will keep on taking steps to separate waste and search for processing sites where waste can be recycled.

The Asahi Kasei Group has been working toward the goal of zero landfill waste plastic. Because mixed waste could not be separated sufficiently and temporary waste could not be recycled, the amount of waste plastic sent to landfill in fiscal 2022 was 1.5 tons, failing to achieve our target. We will continue to promote recycling initiatives.

Waste containing PCBs3 is stored under strict control in stainless steel vessels. Plans for disposal are advancing, including for waste with minimal amounts of PCBs. We are systematically identifying and replacing electrical equipment containing PCBs and proceeding with their disposal.

We enhanced our management of off-site treatment of industrial waste by expanding the use of electronic manifests. We also performed periodic on-site inspections of consigned firms to ensure that proper treatment is performed in accordance with sound systems of control.

- 1 Recycling rate:Percentage of chemical recycling and material recycling

- 2 Non-recycling rate:Percentage of heat recovery, weight reduction, and landfill disposal

- 3PCBs (polychlorinated biphenyls) are persistent and pose a risk to the living environment and human health. Their manufacture and use are essentially prohibited in Japan.

FY2022 flow of industrial waste

FY2022 flow of industrial waste

Waste generated

Waste generated Recycling rate

Recycling rate

Landfill volume of plastic waste

Landfill volume of plastic waste

Reducing industrial waste from construction materials and housing businesses

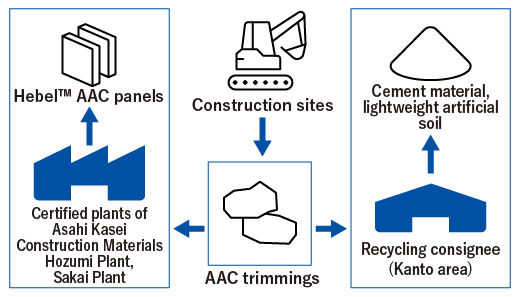

Asahi Kasei Construction Materials recycles trimmings of Hebel™ autoclaved aerated concrete (AAC) panels in its own plants and others, utilizing its certification for "wide-area recycling"* which permits the transport of waste from different construction sites. Asahi Kasei Homes is also reducing the volume of waste as well as implementing sorted waste collection at housing construction sites. With these measures, waste for final disposal has been reduced to zero at new construction sites.

Recycle flow for trimmings of Hebel™ AAC panels

Recycle flow for trimmings of Hebel™ AAC panels

- * Certificate for wide-area recycling: For certain parties, who perform recycling in a wide-area, Japan's Minister of the Environment eliminates the need to obtain separate waste transport permits for each local area. The system was established to promote further recycling of industrial waste.

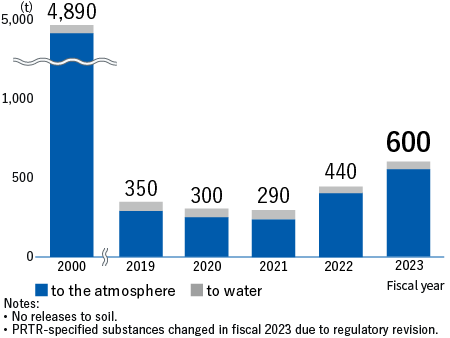

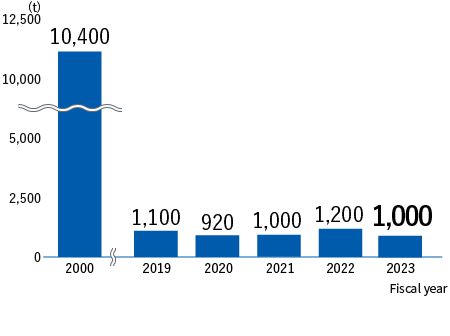

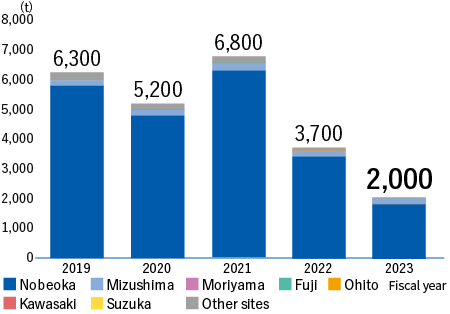

Reducing emissions of chemical substances

The Asahi Kasei Group works to reduce the release of chemicals substances specified in the PRTR1 Law and other chemical substances which we have voluntarily designated for reduction with priority based on the degree of hazardousness and amount of release. As shown in the graphs below, releases of PRTR-specified substances and VOC2 emissions were reduced by 91% and 89%, respectively from fiscal 2000. We will continue to enhance control of operation and equipment to prevent any accidental release.

From fiscal 2021, the calculated amount of leaked fluorocarbons are aggregated for the Asahi Kasei Group as a whole. The Asahi Kasei Group’s calculated amount of leaked fluorocarbons in fiscal 2022 was 1,327 tons of CO2-equivalent.

Releases of PRTR-specified substances

Releases of PRTR-specified substances Releases of VOCs

Releases of VOCs

- 1PRTR:Pollutant release and transfer register. Under the PRTR Law, releases to the environment and off-site transfers of specific hazardous chemical substances must be monitored and recorded for each production facility and operating site. Results are reported to the government, which publishes aggregated results.

- 2VOC:Volatile organic compound. Although the term generally applies to any organic compound which is in gaseous state at the time of release, regulations for the control of their release exclude methane and some fluorocarbons which do not form oxidants. However, methane and some fluorocarbons are excluded from VOC regulations on the grounds that they do not form oxidants.

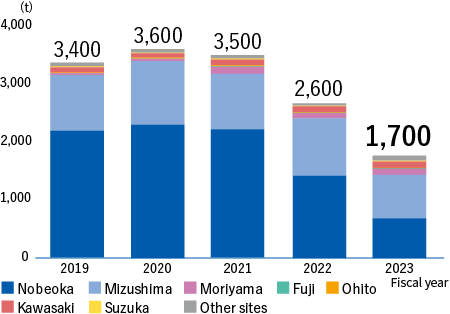

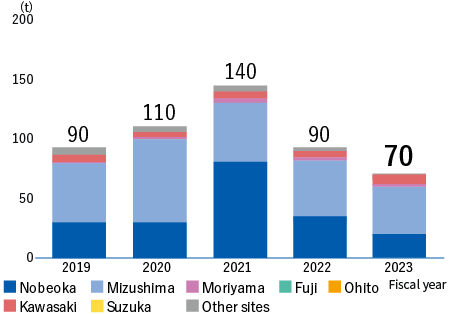

Preventing air pollution

The Asahi Kasei Group works to control emissions and prevent spills in order to avoid the pollution of air, water, soil, and groundwater. Measures to prevent noxious odors include the installation of exhaust gas absorption equipment and increasing the capacity of our wastewater treatment facilities. To prevent soil pollution, we perform tests and take appropriate measures in accordance with the Soil Contamination Countermeasures Act and related regulations. Substances covered by the Air Pollution Control Act are managed within regulatory standards.

SOx emissions

SOx emissions NOx emissions

NOx emissions

Soot and dust emissions

Soot and dust emissions

Effective resource use

As indicated by the Osaka Blue Ocean Vision at the G20 summit in 2019, the issue of marine plastic waste will require global cooperation to solve. In order to understand how marine microplastics are generated, we are working in collaboration with Kyushu University and participating in awareness-raising activities with industry groups dealing with proper use and disposal of plastics. It is important to make effective use of used plastic resources, so we also promote the 3Rs (Reduce, Reuse, Recycle).

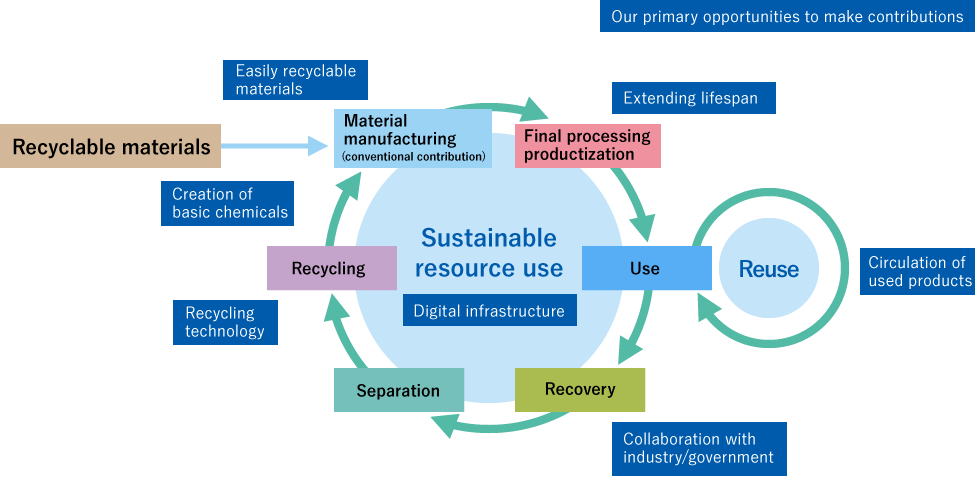

Approach to the Circular Economy

Approach to the Circular Economy

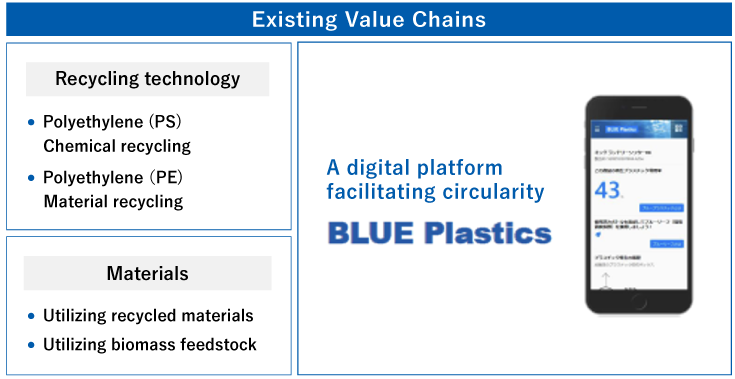

Initiative for Achieving a Circular Economy

Plastics recycling project

As part of our sustainability efforts, which are symbolized by the SDGs (Sustainable Development Goals), we are working with academia and other companies to achieve a circular economy.

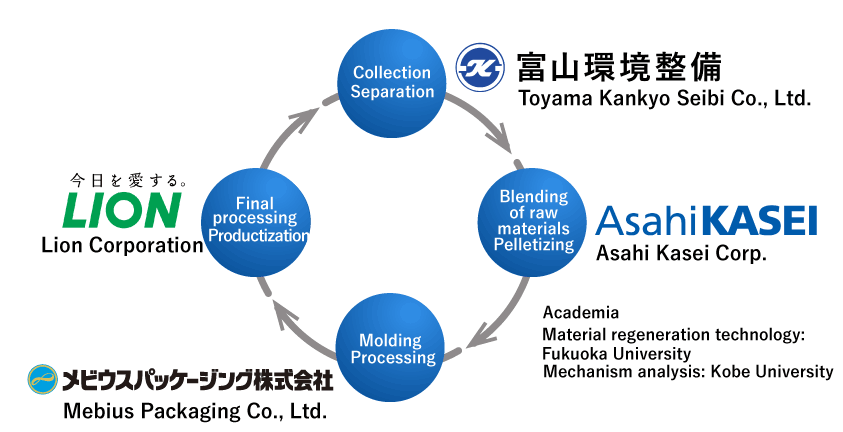

For the material recycling of polyethylene, we have launched a plastics recycling project* with the technical support of IBM Japan, Ltd. We are striving to make a circular economy a reality through collaboration with recycling company Toyama Kankyo Seibi; Mebius Packaging Co., Ltd., which specializes in molding and final product processes; and brand owner Lion Corporation.

- * Overview of the plastics recycling project

The project was launched by Asahi Kasei Corp. to create a digital platform that promotes resource recycling. IBM Japan will support the construction of the digital platform by utilizing blockchain technology that runs on the IBM Cloud. Blockchain technology is an irreversible database technology that maintains a continuous record of operations, which ensures traceability as it is accessible to all parties involved and cannot be altered. Toyama Kankyo Seibi, Mebius Packaging Co., Ltd., and Lion Corporation, which together specialize in the collection, pelletizing, molding, and conversion of waste into final products, will collaborate using IBM Japan’s blockchain technology to accelerate the achievement of a circular economy.