TOPCreating for TomorrowTomorrow’s Stories From Fashion to Medical Care: How Asahi Kasei’s Core Technologies and Innovations Drive the Evolution of Business

From Fashion to Medical Care: How Asahi Kasei’s Core Technologies and Innovations Drive the Evolution of Business

March 13, 2024

In the 1920s, when agriculture was a major segment of the economy, Asahi Kasei became the first company in Japan to synthesize ammonia for the manufacture of fertilizer. This not only became the basis for an industrial chemicals business, but also led to the development of a fibers business. After more than 100 years of changes and challenges since our founding, we currently have businesses in the three sectors of Material, Homes, and Health Care. The growth of Health Care in particular has been remarkable. At the root of our businesses, and behind our transformation, are the core technologies and innovations that have been passed down from generation to generation since our foundation. Throughout our history, the people in our company have inherited our predecessors' spirit of taking challenges to work toward the future through core technologies and innovations.

Contents

- 1. Enriching people’s food and clothing – the origins of our core technologies and innovations

- 2. From fashion to medical care – entering the Health Care sector by cultivating core technology

- 3. Contributions during the COVID-19 pandemic – Planova™ virus removal filters

- 4. Supporting the continual expansion and evolution of technologies

- 5. The time is ripe for chemistry and Asahi Kasei

Enriching people’s food and clothing – the origins of our core technologies and innovations

In 1922, our founder Shitagau Noguchi began construction of a fertilizer plant in Nobeoka City, Miyazaki Prefecture, Japan, and a hydroelectric plant upstream on the Gokase River that flows through the city, to supply power to the fertilizer plant. He wanted to help improve the productivity of agriculture which provides food to sustain people's lives. The following year, Asahi Kasei became the first company in Japan to manufacture synthetic ammonia, an essential ingredient for fertilizers. This is how the history of our company began, utilizing the plentiful water resources in the region of Nobeoka.

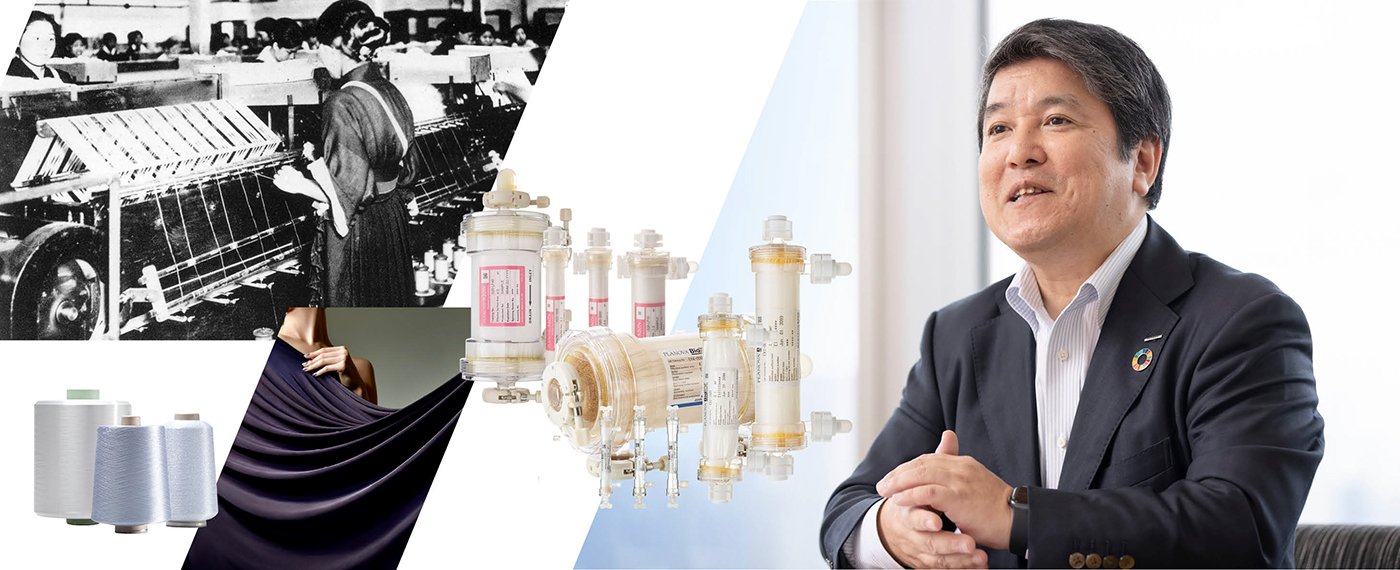

At the time, the most common clothing in Japan was the silk kimono. Noguchi felt that people's standard of living would improve if high-quality fabric could be made more affordable. In 1924, Asahi Kasei began manufacturing viscose rayon, a regenerated cellulose fiber. The aspiration to help improve people’s standard of living with better food and clothing was the origin of our business, and this led to technologies and innovations that we still use today.

We then began manufacturing Bemberg™ cupro, another regenerated cellulose fiber, in 1931. We expanded our fibers business throughout the 1920s to 1950s mainly focusing on viscose rayon and Bemberg™ cupro, which are regenerated fibers. In 1957, we began manufacturing Cashmilon acrylic, a synthetic fiber, further enhancing our knowledge and technology for fibers.

The fibers business began in 1924 with the manufacture of viscose rayon (photo shows the Zeze Plant, Shiga Prefecture, ca. 1928)

The fibers business began in 1924 with the manufacture of viscose rayon (photo shows the Zeze Plant, Shiga Prefecture, ca. 1928) Bemberg™ cupro is a preferred material for suit linings and other apparel around the world

Bemberg™ cupro is a preferred material for suit linings and other apparel around the world

From fashion to medical care – entering the Health Care sector by cultivating core technology

Although Cashmilon acrylic benefited from growing demand for the synthetic fiber in the apparel industry in the early 1970s, Bemberg™ struggled. While a new synthetic fiber plant was under construction, the Bemberg™ researchers, whose number had been reduced to only two, were desperately searching for new applications for the material outside of apparel. They considered what the world needed, and how they could use Bemberg™ technology to meet those needs. As a result, they decided to develop artificial kidneys using the regenerated cellulose material of Bemberg™ for hollow-fiber membranes. In the field of medical care, there were high expectations for artificial kidneys as a medical device for dialysis treatment in patients with renal failure. We began commercial manufacture of artificial kidneys in 1975. Although it was challenging to develop such an application, the successful development based on our technological strength in the fibers business resulted in our company’s expansion into the Health Care sector.

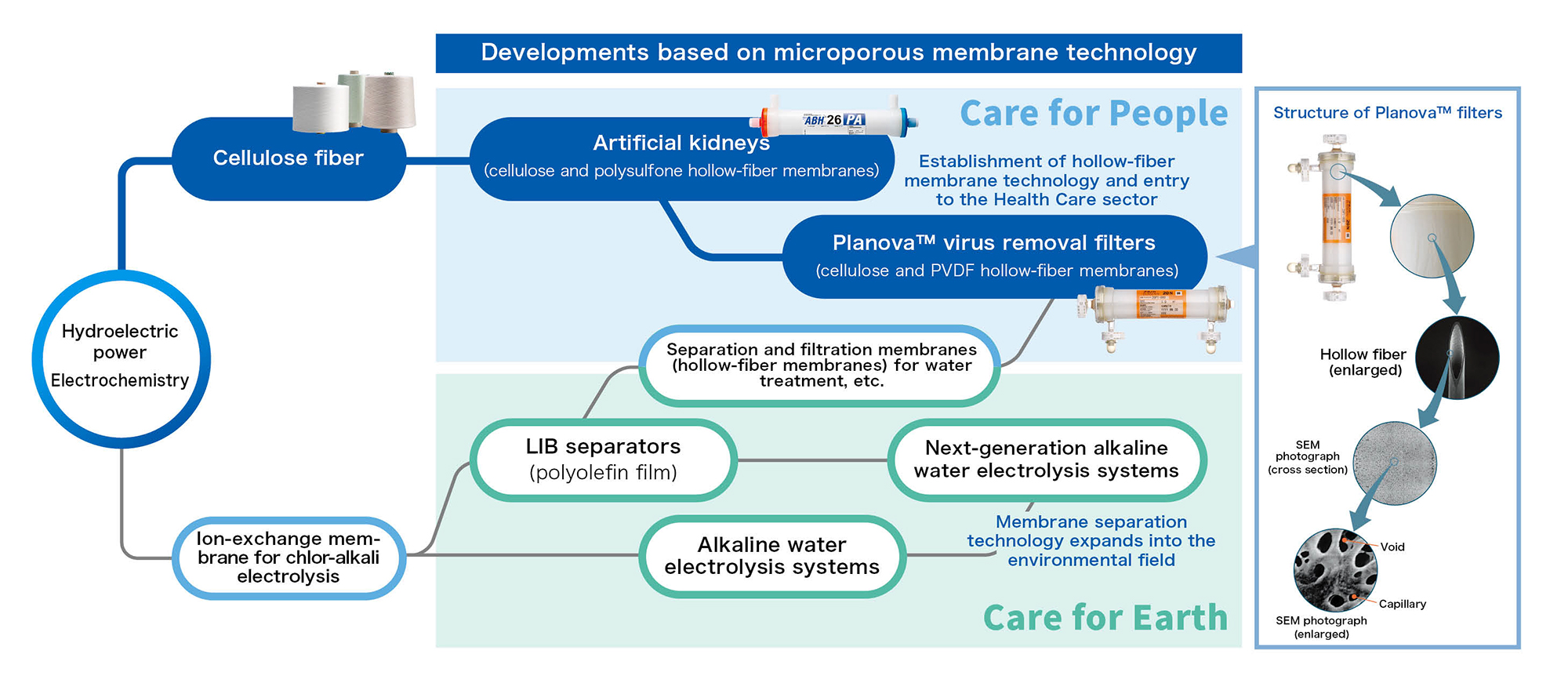

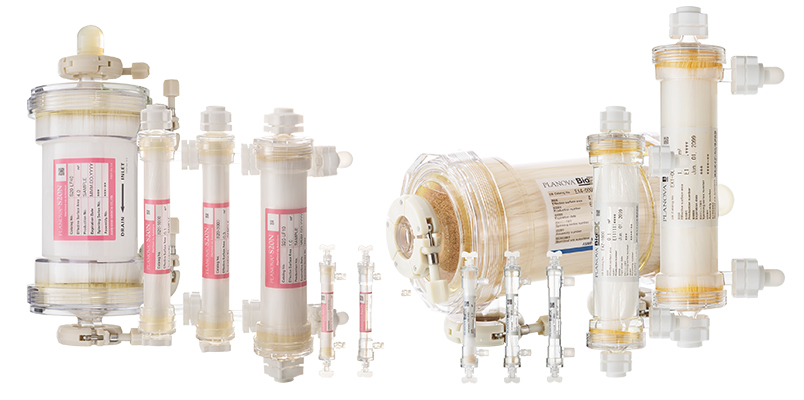

With the development of artificial kidneys, hollow-fiber membrane technology became a new core technology. In 1989, this technology was applied to create another new product: Planova™ virus removal filters. Made with hollow-fiber membranes Planova™ is used in the manufacturing and development processes for plasma derivatives and biopharmaceuticals. A hollow-fiber membrane is a narrow hollow tube like a tiny straw, with the membrane wall filled with microscopic pores. When pharmaceutical ingredients flow through the inside of the hollow fibers, the microscopic pores can separate and remove viruses and other impurities. Technologies such as hollow-fiber membrane technology, which utilize a membrane with micropores for separation, are categorized as microporous membrane technology, which has itself become a core technology of Asahi Kasei that traces back to our founding. We also use other forms of microporous membrane technology in the field of the environment, including lithium-ion battery (LIB) separators and large-scale alkaline water electrolysis systems for manufacturing green hydrogen.

From fashion to medical care. We started by synthesizing ammonia and expanded from fiber technology into the Health Care sector. Our cultivation of core technologies and our history of innovation have made us the company we are today, contributing to life and living for people around the world.

Developments based on microporous membrane technology

Developments based on microporous membrane technology

Contributions during the COVID-19 pandemic – Planova™ virus removal filters

The Planova™ business is operated by Asahi Kasei Medical. During the COVID-19 pandemic, demand for Planova™ rose among pharmaceutical companies around the world. As many companies tried to quickly develop treatments for COVID-19, there was a greater need for Planova™ filters which are used in the manufacturing and development process of pharmaceuticals. But it was a huge challenge to increase the production of Planova™ filters under difficult circumstances. The personnel of the plant reflect on the struggle.

“Our company has proven technical capabilities, high-quality products, and a history of being faithful to our customers. We are proud that we were able to live up to their trust and expectations during such a challenging time.”

We also received a certificate of appreciation from a consortium of major pharmaceutical companies. Even after being on the market for over 30 years, Planova™ met the world's expectations from behind the scenes during a global crisis, leading to a unique contribution through our core technologies and innovations.

Planova™ virus removal filters

Planova™ virus removal filters Personnel of the Nobeoka Plant who strove to increase production of Planova™

Personnel of the Nobeoka Plant who strove to increase production of Planova™

Supporting the continual expansion and evolution of technologies

Masami Takenaka, who has led our company’s R&D, emphasizes that it was the strong determination of our predecessors, passed down since our founding, which led to the development of medical devices based on technology for fibers used in apparel, a field completely different from Health Care.

“Our company has many core technologies established by our predecessors, but there is a common aspect to the creation and improvement of these technologies. That is a strong determination to make life better for people around the world. To create something new from scratch, one encounters numerous challenges and obstacles in R&D. It can be a long journey before results are attained, and we are constantly faced with the possibility of failure. In order to continue to face these difficulties, we need a strong determination to contribute to the world. This atmosphere is deeply rooted in our R&D, continuing to address the world's needs in every era. We have developed our current wide range of core technologies and businesses as a result.”

We want to use our technologies to solve pressing issues in the world. This aspiration has continued to drive the creation of new technologies and products. Looking back, our technologies have expanded and evolved in ways that were unimaginable 100 years ago.

Lead Executive Officer Masami Takenaka, who has lead research and development

Lead Executive Officer Masami Takenaka, who has lead research and development

The time is ripe for chemistry and Asahi Kasei

In closing, Takenaka spoke about the future of our company’s technology and innovation. “I believe the time is ripe for chemistry and Asahi Kasei. Chemical technology can change one substance into another one using minimal energy. Moving forward, innovation that enables continual contribution to the world is essential. At Asahi Kasei, we foster an environment where employees can interact smoothly and seamlessly engage in R&D with new ideas being created from the differences between our diverse people and technologies. In this way, I hope that we will continue to create innovations and play a major role in achieving a circular economy. However, we cannot do this by ourselves. It is important that we remain attentive to cutting-edge global technologies, and strengthen collaboration with partners around the world. We will further cultivate our core technologies as we transform for a better future.” Going forward, we will continue to make innovations that change the world, utilizing our chemistry-based technological capability.

- Note:Titles and contents are current as of the interview date.

Related information

Other stories

High ionic conductive electrolyte for next-generation batteries: Business advancement and market development through co-creation

High ionic conductive electrolyte for next-generation batteries: Business advancement and market development through co-creation Transforming the ion-exchange membrane business model to enable stable supply of caustic soda and chlorine

Transforming the ion-exchange membrane business model to enable stable supply of caustic soda and chlorine The Road to Solvent ZERO

The Road to Solvent ZERO Pioneering the future of mobility through semiconductors

Pioneering the future of mobility through semiconductors Be a Connector: A New Site for Co-Creation in the Semiconductor Business

Be a Connector: A New Site for Co-Creation in the Semiconductor Business Asahi Kasei’s Ideal Hydrogen Society and World-leading Hydrogen Production Technology

Asahi Kasei’s Ideal Hydrogen Society and World-leading Hydrogen Production Technology The Asahi Kasei Judo Team Holds Workshops That Convey World-Class Spirit and Techniques to Future Generations

The Asahi Kasei Judo Team Holds Workshops That Convey World-Class Spirit and Techniques to Future Generations Asahi Kasei's Track Team Brings a Community Together Through a Passion for Sports

Asahi Kasei's Track Team Brings a Community Together Through a Passion for Sports