TOPCreating for TomorrowThe Road to Solvent ZERO

The Road to Solvent ZERO

February 6, 2025

Flexographic printing is widely used for printing on cardboard and product packaging. Photopolymers from Asahi Kasei are used for the flexographic printing plates. Let’s look at the "Solvent ZERO" project, which aims for a complete transition to solvent-free photopolymer plates in flexographic printing worldwide.

Contents

Flexographic printing widely adopted in Europe

It’s widely known that attractive packaging encourages consumers to purchase a product. In many parts of Asia, gravure printing is used for the packaging of cosmetics and food products, where appearance is important. Although gravure printing provides fine gradation, it generally uses solvent-based ink. Flexographic printing, in contrast, allows the use of water-based ink. With increasing environmental awareness in recent years, flexographic printing has become mainstream in the packaging market, especially in Europe, as printers reduce their use of solvent-based inks which cause VOC (volatile organic compound) emissions. Asahi Kasei is a pioneer in photopolymer plates for flexographic printing, having manufactured AFP™ (Asahi Flexo Plate) for over 40 years.

The long-awaited solvent-free product

Akihiro Kato was handling overseas sales of AFP™ in the 1990s. He never forgot one visit to a customer's plate-making room in Asia. Although water-based ink could be used for flexographic printing, solvents were still needed for the washout step of the plate-making process. Kato was concerned by his customer’s poorly ventilated plate-making room, filled with the smell of solvents. The workers had no protective goggles or gloves. Even more troubling, Kato could see a baby sleeping in the adjacent room exposed to solvent-tainted air. If only he could offer a product that allowed solvent-free plate-making, Kato thought, such a disturbing scene need never occur again. But there was no technology to enable this at that time.

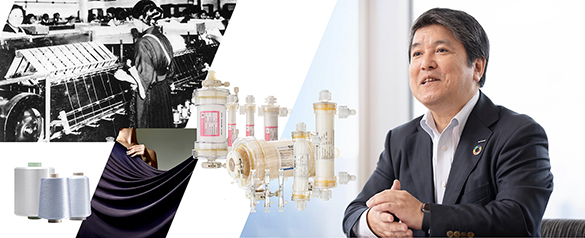

About 20 years later, Kato became Senior General Manager of the Photoproducts Division. Asahi Kasei’s photopolymer technology had advanced remarkably in the meantime, resulting in AWP™ (Asahi Water-washable Plate) allowing a completely solvent-free plate-making process. “AWP™ is just the product I wished we could have had 20 years ago,” muses Kato. Fueled by the frustration of that time and the joy of fulfilling a long-awaited dream, Kato is promoting the Solvent ZERO project aiming to sell only solvent-free products by 2030.

Akihiro Kato, Senior General Manager of the Photoproducts Division

Akihiro Kato, Senior General Manager of the Photoproducts Division AWP™ (Asahi Water-washable Plate)

AWP™ (Asahi Water-washable Plate)

A breakthrough in the printing industry

But it’s not easy to convince customers to switch from the mainstay AFP™ product line to the new AWP™ product line. First of all, they would need to buy new equipment, since AFP™ and AWP™ use different plate-making equipment. Plate-making companies needed to make significant investment in new equipment in order to switch. Additionally, there was a perceived risk of change to the printing quality. The plate-making companies and the printing companies that use the plates need to meet high standards for printing quality demanded by the brand owners who use the packaging for their products. Such companies are apprehensive about changing to an unfamiliar technology, since they don’t want to risk any change in printing quality. Furthermore, in Japan flexographic printing was not considered suitable to printing high-quality images. In the Japanese printing industry, it was believed that high-quality printing should be done by gravure. As a result, flexographic printing overall was used much less in Japan than in other countries.

To overcome this situation, the sales team decided to approach not only the plate-making and printing companies but also the brand owners who use the printed packaging. They wanted to explain how adopting AWP™ instead of AFP™ would not only eliminate the need for solvents in the development process and improve the working environment, but also contribute to reduced air pollution from VOC emissions which can cause water pollution by contaminating the rain. This entailed making calls on companies in different industries and significantly larger in scale than they traditionally would. The first to be approached was the Suntory Group. If they could get AWP™ adopted in the label printing of the famous brand Suntory Natural Mineral Water, it would be a significant achievement, serving as a breakthrough for other projects. Arata Ohnoko from Marketing & Sales and Yuzo Fujiki from Technology & Development took on the task with determination.

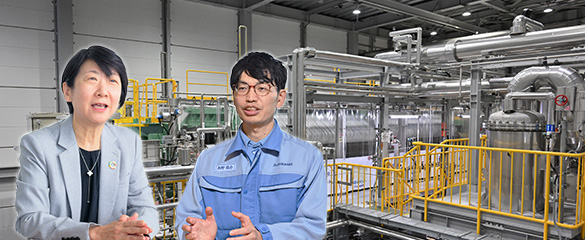

Arata Ohnoko of Photoproducts Marketing & Sales Dept.

Arata Ohnoko of Photoproducts Marketing & Sales Dept.  Yuzo Fujiki of Photoproducts Technology & Development Dept.

Yuzo Fujiki of Photoproducts Technology & Development Dept.

The project was a big opportunity, but it was challenging. It was no simple matter to work in collaboration with the plate-making and printing companies in order to meet the standards in each process of AWP manufacturing, plate-making, and printing. In addition, the Suntory Group had extremely high standards for the design and colors of the labels of Suntory Natural Mineral Water, one of their flagship products. Fujiki performed trial after trial, identified the causes of variations and made numerous improvements to meet the standards, while coordinating with the plate-making and printing companies. Even regarding issues that did not seem to be caused by Asahi Kasei, they worked sincerely to help identify the cause and implement a solution. At times, the plate-making company got tired of being asked to make so many improvements. Ohnoko would strive to mend the relationship and keep the project moving forward.

Uncompromising determination bore fruit

In the final stage of the project, there was one last hurdle. They couldn’t quite get the exact same colors as requested. Suntory Natural Mineral Water is produced at four plants: Southern Alps, Northern Alps, Oku-Daisen, and Aso, each with a different label design. This attention to detail is one of the reasons for the product’s strong brand and high market share.* The client’s specifications for the colors were extremely precise. As they were struggling to get the colors right, one of Suntory’s marketing personnel said, “Could you distinguish between different brands of mineral water in a blind taste test? There are few people who can. We consider the label to be very important for consumers to choose our product.” Fujiki was struck by those words, realizing that just as he and his colleagues at Asahi Kasei were passionate about Solvent ZERO, the client was passionate about their label design. The team redoubled their efforts to meet the uncompromising color specifications. At last, their determination bore fruit, and AWP™ was adopted for the labels of Suntory Natural Mineral Water Aso. Bottles with those labels attached are now in commercial distribution.

- *Based on internal research by Suntory Beverage & Food Limited for the domestic Japanese market in 2022.

Suntory Natural Mineral Water Aso with a label made using AWP™

Suntory Natural Mineral Water Aso with a label made using AWP™

Caring for people drives the team

“At overwhelming speed.” Kato has a habit of using this phrase, and it has become common parlance in the division. Sometimes it seems unrealistic, but nobody wants to miss an opportunity to move forward toward their goal of Solvent ZERO by 2030. Everyone in Asahi Kasei's Photoproducts Division is striving to advance at overwhelming speed for the global environment as well as the workplace environment in the printing industry. Their continuous effort for Solvent ZERO at overwhelming speed shows how motivating care for others can be.

- Note:Titles and contents are current as of the interview date.

Related information

Other stories

High ionic conductive electrolyte for next-generation batteries: Business advancement and market development through co-creation

High ionic conductive electrolyte for next-generation batteries: Business advancement and market development through co-creation Transforming the ion-exchange membrane business model to enable stable supply of caustic soda and chlorine

Transforming the ion-exchange membrane business model to enable stable supply of caustic soda and chlorine Be a Connector: A New Site for Co-Creation in the Semiconductor Business

Be a Connector: A New Site for Co-Creation in the Semiconductor Business Pioneering the future of mobility through semiconductors

Pioneering the future of mobility through semiconductors From Fashion to Medical Care: How Asahi Kasei’s Core Technologies and Innovations Drive the Evolution of Business

From Fashion to Medical Care: How Asahi Kasei’s Core Technologies and Innovations Drive the Evolution of Business Asahi Kasei’s Ideal Hydrogen Society and World-leading Hydrogen Production Technology

Asahi Kasei’s Ideal Hydrogen Society and World-leading Hydrogen Production Technology The Asahi Kasei Judo Team Holds Workshops That Convey World-Class Spirit and Techniques to Future Generations

The Asahi Kasei Judo Team Holds Workshops That Convey World-Class Spirit and Techniques to Future Generations Asahi Kasei's Track Team Brings a Community Together Through a Passion for Sports

Asahi Kasei's Track Team Brings a Community Together Through a Passion for Sports