Asahi Kasei launches new series of Sunfort™ dry film photoresist as material for back-end processing of advanced semiconductor packaging used in AI servers

May 26, 2025

Asahi Kasei Corp.

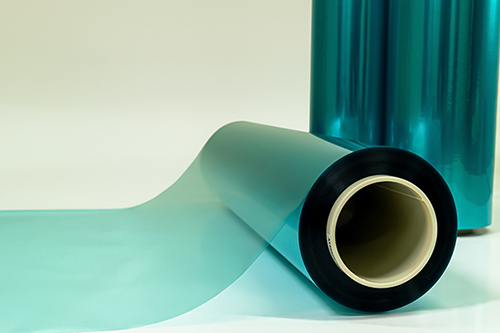

Asahi Kasei has developed the TA Series of Sunfort™ dry film photoresist as a new product designed to meet growing demand in the field of advanced semiconductor packages used in applications such as artificial intelligence (AI) servers. This product is positioned as a strategic offering within Asahi Kasei's Material sector, aiming to strengthen its footprint in the rapidly growing market for next-generation chip packaging. The dry film delivers an ultra-high resolution with conventional stepper exposure systems and laser direct imaging (LDI) systems, which transfer circuit patterns onto substrates during packaging, contributing to enhanced performance and precision in back-end processes.

Sunfort™ dry film photoresist

Sunfort™ dry film photoresist

Sunfort™ dry film photoresist is a mainstay of Asahi Kasei’s Electronics business, comprising electronic materials and electronic components, which is positioned as a First Priority business to drive growth from fiscal 2025–2027 under the medium-term management plan “Trailblaze Together.”

Interposers serve as a bridge between chips and substrates and are used along with package substrates in advanced semiconductor packages. These components require a large area, high-multilayer structures, and increasingly sophisticated technologies for forming high-density microwiring. In photolithography, liquid resist has long been the mainstream photoresist material for the redistribution layer (RDL) due to its superior resolution. In contrast, dry film photoresist offers advantages for panel-level processing (which involves larger surface area than conventional wafer-level processing), such as ease of handling and ease of processing on both the top and bottom sides of the substrate, but have not been adopted for RDL formation due to limited resolution performance.

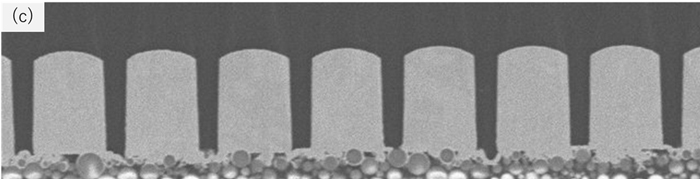

Developed based on Asahi Kasei’s long experience with photosensitive material together with new material design, the TA Series enables fine wiring formation in panel-level packages and similar applications. The TA Series allows for patterning with a resist width of 1.0 µm using LDI exposure in the 4 µm pitch design required for RDL formation (see Figures a and b). The resulting fine resist pattern can be plated by a semi-additive process (SAP, a method for forming fine conductive patterns using partial electroplating) followed by resist stripping to form a 3 µm wide plating pattern in a 4 µm pitch design (Figure c).

![Micro-pattern of 7 µm thick TA Series formed by LDI<br/>

(a) Resist pattern (L/S = 1.0/3.0 µm; L/S = Line / Space in micro-wiring [µm]) front side<br/>

(b) Resist pattern (L/S = 1.0/3.0 µm) oblique](ibja4e00000005y6-img/e250526_02.jpg) Micro-pattern of 7 µm thick TA Series formed by LDI

Micro-pattern of 7 µm thick TA Series formed by LDI

(a) Resist pattern (L/S = 1.0/3.0 µm; L/S = Line / Space in micro-wiring [µm]) front side

(b) Resist pattern (L/S = 1.0/3.0 µm) oblique

(c) Pattern cross section after resist stripping (Plating line width / Space width = 3.0/1.0 µm)

(c) Pattern cross section after resist stripping (Plating line width / Space width = 3.0/1.0 µm)

Sunfort™ dry film photoresist will continue to play a key role in developing panel-level packaging technology as panel sizes grow. The new TA Series allows manufacturers to achieve finer wiring with greater production efficiency, helping to reduce cost and increase yield in advanced semiconductor packaging. Asahi Kasei’s TA Series comes at a pivotal time as demand in AI, automotive, and IoT markets grows.

“The development of the TA Series comes after years of close collaboration with our customers and a deep understanding of their most pressing pain points. Through this development, we address the evolving requirements of semiconductor packaging in AI, automotive, and IoT applications,” said Yu Hasegawa, Managing Executive and Senior General Manager of the Electronics Interconnecting Materials Division at Asahi Kasei. “With growing demand, particularly in Asia and North America, we at Asahi Kasei are enhancing our global support framework to deliver timely solutions and technical services tailored to regional needs.”

To learn more about Asahi Kasei’s advanced semiconductor package solutions, visit https://www.asahi-kasei.co.jp/sunfort/en/products/ta.html.

About Asahi Kasei

The Asahi Kasei Group contributes to life and living for people worldwide. Since its foundation in 1922 with ammonia and cellulose fiber business, Asahi Kasei has consistently grown through the proactive transformation of its business portfolio to meet the evolving needs of every age. With more than 50,000 employees worldwide, the company contributes to sustainable society by providing solutions to the world’s challenges through its three business sectors of Material, Homes, and Healthcare. For more information, visit https://www.asahi-kasei.com.

Asahi Kasei is also dedicated to sustainability initiatives and is contributing to reaching a carbon neutral society by 2050. To learn more, visit https://www.asahi-kasei.com/sustainability/.