TOPCreating for TomorrowTomorrow’s Stories High ionic conductive electrolyte for next-generation batteries: Business advancement and market development through co-creation

High ionic conductive electrolyte for next-generation batteries: Business advancement and market development through co-creation

December 25, 2025

Technological innovation for lithium-ion batteries (LIBs) is accelerating as EVs become more widespread. At the same time, issues of safety and the environmental impact of LIBs are emerging. As one solution, Asahi Kasei is offering high ionic conductive electrolyte. Business advancement and market development are being performed simultaneously in Europe and China. Let’s see how Asahi Kasei employees are striving to get high ionic conductive electrolyte adopted around the world.

Contents

The LIB as a low environmental impact alternative that doesn’t use lead

While the speed of adoption varies, EVs are increasing around the world. Even if the main battery is an LIB, EVs still tend to have an auxiliary 12 V lead-acid battery for the lights, infotainment system, etc.

While lead-acid batteries are highly reliable with a long-established track record, there is a concern of lead contaminating the environment if they aren’t properly recycled. In regions where recycling is poorly managed, lead poisoning is a serious health issue.*

Asahi Kasei is proposing that 12 V auxiliary batteries be changed to LIBs with low environmental impact and dramatically improved service life. The company is also promoting solutions to LIB shortcomings for faster charging, higher output at low temperature, and longer service life at high temperature.

Advancing as a pioneer

As a pioneer of LIB technology, in 2010 Asahi Kasei began studying the use of acetonitrile as a solvent in high ionic conductive electrolyte to overcome the shortcomings of conventional LIBs. Using acetonitrile in the electrolyte speeds up migration of lithium ions between the cathode and anode, in theory allowing higher output, better functioning at low-temperature, and faster charging. But if you simply replace the electrolyte with acetonitrile, it decomposes when one attempts to charge the battery, making it unusable. Throughout the battery industry, acetonitrile electrolyte came to be seen as impractical, however good in theory.

At Asahi Kasei’s Yoshino Laboratory, headed by Honorary Fellow Dr. Akira Yoshino who invented the LIB, researchers still believed in acetonitrile. They were sure it would be a major breakthrough if they could find a way to make acetonitrile usable. After years of effort, the basic technology for high ionic conductive electrolyte using acetonitrile was established in 2016.

Working in Technology Policy at Corporate Research & Development, Yuto Iizuka recognized the great potential of this high ionic conductive electrolyte. In 2018 he launched a project to develop the market in Europe, and went to Germany. At the time, Europe was the region most aggressively pressing for commercialization and adoption of EVs.

Yuto Iizuka of Corporate Research & Development, who led the electrolyte project

Yuto Iizuka of Corporate Research & Development, who led the electrolyte project

But Asahi Kasei didn’t have connections in the European EV market. Iizuka went to every relevant exhibition and conference in Europe he could, but struggled to make connections. Though the company name Asahi Kasei is well recognized in Japan, it was almost completely unknown in the European automotive industry. In addition to the lack of name recognition, Iizuka was hampered by cultural differences.

“For marketing in Japan, we just tout the features of our product. In Europe that doesn’t work. You need to gain trust by explaining the weak points as well as the strong points. As I got used to their way of communicating, little by little I began to get into serious negotiations.”

They set up an electrolyte lab in Germany. Samples of the high ionic conductive electrolyte were provided to researchers at universities and national institutions as well as vehicle manufacturers and battery manufacturers. Their evaluations were disappointing. The electrolyte still wasn’t ready for commercialization. But the team remained confident that they could overcome the challenge and create a solution that would meet customer needs.

Iizuka continued to work closely with researchers in Japan delving deeply into the basic principles of the technology and researchers in Europe dealing with specific customer issues. A turning point finally came after three long years of marketing. They joined the HEADLINE* project of the German Federal Ministry of Education and Research on the recommendation of a German national research institute they were interacting with. This led to joint development of next-generation batteries with government support.

In June 2024 they successfully completed a “proof of concept” (PoC) for an LIB using the high ionic conductive electrolyte, and in November 2025 the technology was licensed to EAS Batteries GmbH, a participant in the HEADLINE project.

Even as new business and market development were advancing in Europe, the Chinese market for EV batteries quickly rose to prominence. For the high ionic conductive electrolyte to really be successful, it needed to succeed in China as well.

Researchers at the electrolyte lab in Europe

Researchers at the electrolyte lab in Europe Electrolyte researchers in Japan

Electrolyte researchers in Japan

Developing the Chinese market

While Iizuka’s team was busy in Europe, Toshihiro Toba was in China working to develop the Chinese market for Asahi Kasei’s businesses. China has a distinctive business culture, with specialized knowledge needed to develop new markets. But Toba felt Asahi Kasei had an advantage by being diversified across different sectors, a corporate attribute which is highly regarded in China.

Toba suggested that a dedicated marketing team be established to accelerate Chinese market development, and this was done in 2020. This team handled marketing activity for several Asahi Kasei businesses in China, in the automotive industry and other areas. They worked to drive strategic advancement in the Chinese market for the Asahi Kasei Group as a whole.

Toshihiro Toba, General Manager of Market Development at Asahi Kasei China

Toshihiro Toba, General Manager of Market Development at Asahi Kasei China

Developing the Chinese market was a hard process, not least because of Asahi Kasei’s low name recognition. Persistent effort was required just to get a single appointment to meet a potential client. And the team struggled to find a way to make the value of Asahi Kasei’s technology known to customers, in order to achieve effective dialogue.

Toba felt that the China International Import Expo afforded opportunities. This annual event held by the Chinese government features exhibitors from various countries seeking to export their wares to China. Visitors from major Chinese companies attend searching for new business partners. By showcasing various solutions Asahi Kasei offers for current issues in China, Toba believed it would help raise the company’s profile and lead to co-creation of new value together with Chinese companies.

Asahi Kasei first exhibited in 2022. Rather than exhibiting in the chemical manufacturer area, they chose the mechanical equipment area which was closer to final products. The intention was to get Asahi Kasei’s name and technology known on the downstream end of the supply chain. The strategy succeeded and several customer connections were gained.

Just when Toba was mulling over how to further expand business in China, the high ionic conductive electrolyte team consulted him.

Exhibiting strategically without compromise

Iizuka and Toba first met each other in 2024. Toba’s market development team in China was the ideal partner for Iizuka as he considered how to approach the Chinese market. Iizuka thought they should exhibit at a major trade show, but Toba disagreed. Toba felt that smaller conferences focused on battery technology would be more effective. “I really thought it would be better to show our presence at a large venue,” recalls Iizuka. “But Toba insisted that we start with small conferences for battery manufacturers. He was right. We gained a lot more contacts than I expected.”

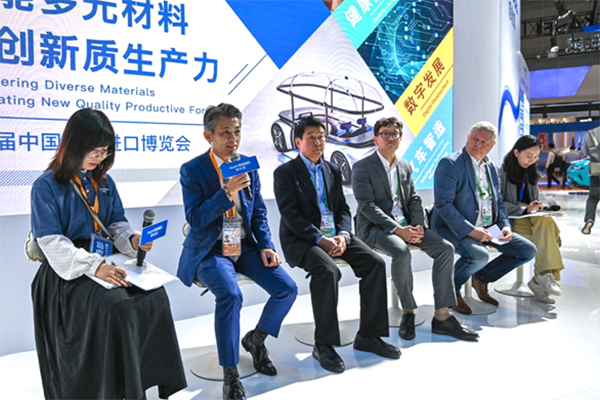

Iizuka decided to make a concerted entry to the Chinese market. They decided to exhibit at the 2024 China International Import Expo. Toba proposed holding a seminar by prominent individuals in the battery industry, and inviting management personnel of battery manufacturers. This would allow them to make a strong impression with the high ionic conductive electrolyte. It turned out to be a great success, and inquiries from Chinese EV manufacturers and battery manufacturers came pouring in.

The high ionic conductive electrolyte was exhibited again at the 2025 China International Import Expo. This time the focus was on the concept of transitioning to LIB for the auxiliary battery. Concrete plans were proposed for co-creation and PoCs in the Chinese battery market, which now leads the world. A lecture and panel discussion were held by leaders of the Chinese auxiliary battery market. Moreover, the license agreement signing ceremony held with EAS was covered by Chinese TV stations and newspapers, resulting in media coverage that further raised Asahi Kasei’s name recognition.

With Asahi Kasei’s exhibit covered by major general media and specialized battery industry media, it was an outstanding event that raised confidence in achieving success in the Chinese market.

The electrolyte symposium at Asahi Kasei’s booth

The electrolyte symposium at Asahi Kasei’s booth License agreement signing ceremony with EAS

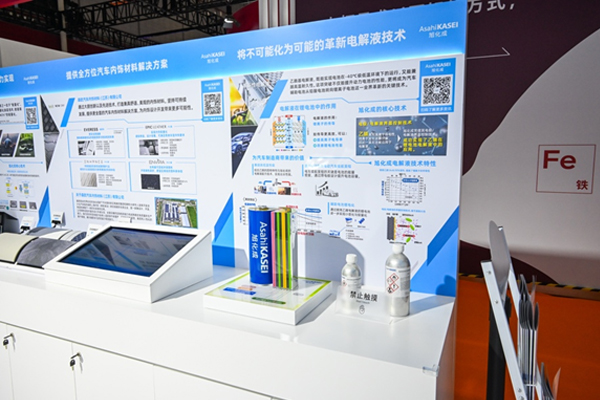

License agreement signing ceremony with EAS High ionic conductive electrolyte display

High ionic conductive electrolyte display

Development requires dependable colleagues

Market development for high ionic conductive electrolyte has been ongoing for around seven years. Iizuka reflects on the importance of colleagues. “I started this market development on my own in Germany. I realize there’s a limit to what one person can do alone. Now we have team members in Germany, China, India, and North America, striving to develop the respective markets using their own judgment as to what works in each region. It's very reassuring.”

Iizuka also speaks highly of Toba, who focuses on market development. “It’s really a joy to work with Toba-san, because he’s so intense. He’s really passionate about his colleagues’ challenges, and gives his full support. We’re fortunate to have him in Asahi Kasei.”

Toba also perceives the value of taking challenges together with colleagues. “No matter how carefully you draw up a strategy, that’s only a framework. Colleagues within the company put it into action, develop it, give shape to it, and drive it forward. It’s the culmination of countless decisions and actions day by day that breathe life into a strategy. We can only advance toward the future we envision because of the many colleagues joining together in the challenge.”

Although studies have begun for a PoC with a Chinese battery manufacturer, there’s still a long way to go before the high ionic conductive electrolyte can be adopted in an EV. But even then Iizuka and Toba won’t stop. They’ll be supporting other colleagues in Asahi Kasei taking on other serious challenges.

Market development team members involved in the China International Import Expo

Market development team members involved in the China International Import Expo

- Note:Titles and contents are current as of the interview date.

Related information

Other stories

Transforming the ion-exchange membrane business model to enable stable supply of caustic soda and chlorine

Transforming the ion-exchange membrane business model to enable stable supply of caustic soda and chlorine The Road to Solvent ZERO

The Road to Solvent ZERO Be a Connector: A New Site for Co-Creation in the Semiconductor Business

Be a Connector: A New Site for Co-Creation in the Semiconductor Business Pioneering the future of mobility through semiconductors

Pioneering the future of mobility through semiconductors From Fashion to Medical Care: How Asahi Kasei’s Core Technologies and Innovations Drive the Evolution of Business

From Fashion to Medical Care: How Asahi Kasei’s Core Technologies and Innovations Drive the Evolution of Business Asahi Kasei’s Ideal Hydrogen Society and World-leading Hydrogen Production Technology

Asahi Kasei’s Ideal Hydrogen Society and World-leading Hydrogen Production Technology The Asahi Kasei Judo Team Holds Workshops That Convey World-Class Spirit and Techniques to Future Generations

The Asahi Kasei Judo Team Holds Workshops That Convey World-Class Spirit and Techniques to Future Generations Asahi Kasei's Track Team Brings a Community Together Through a Passion for Sports

Asahi Kasei's Track Team Brings a Community Together Through a Passion for Sports