TOPCreating for TomorrowTomorrow’s Stories Transforming the ion-exchange membrane business model to enable stable supply of caustic soda and chlorine

Transforming the ion-exchange membrane business model to enable stable supply of caustic soda and chlorine

October 3, 2025

Delivering more value to customers, never taking their trust for granted. Asahi Kasei’s ion-exchange membrane & electrolysis system business is transforming its business model 50 years after commercialization

Contents

- 1. Technology for reduced environmental impact adopted at chlor-alkali plants worldwide

- 2. Not letting customers’ trust lead to complacency

- 3. Customer-orientation as a team

- 4. Conveying proposals more clearly

- 5. Building new relationships through patient dialogue

- 6. Enhancing technical development through data collection

- 7. The challenge continues

Technology for reduced environmental impact adopted at chlor-alkali plants worldwide

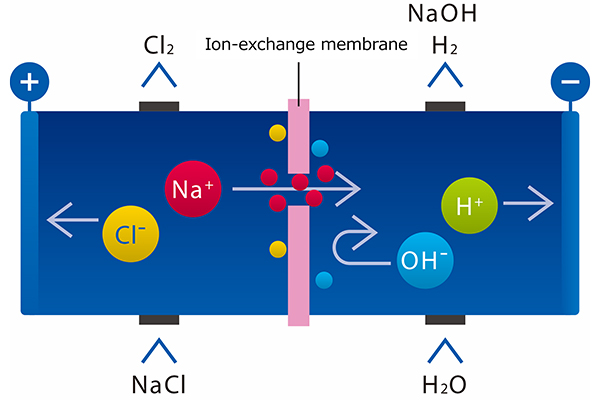

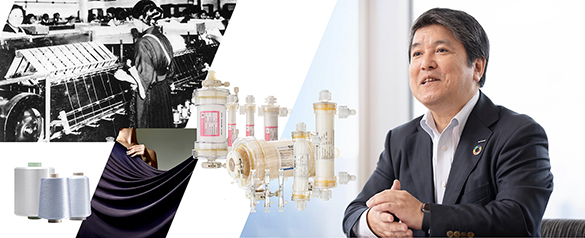

The ion-exchange membrane process for chlor-alkali electrolysis uses ion-exchange membranes in a system to electrolyze brine, producing caustic soda and chlorine. Asahi Kasei led the world with commercial operation of this process. Unlike former processes, the membrane process uses no hazardous substances such as mercury or asbestos, and it consumes less power. This makes it a key technology for reducing the environmental impact* of chlor-alkali plants.

Caustic soda is used across many industries, including in the production of paper, pulp, nonferrous metals, electronic products, pharmaceuticals, and chemical products, as well as water treatment. Chlorine is widely used in disinfectants and bleaching agents, as well as materials for the production of vinyl chloride resins, polyurethane resins, and synthetic rubber. Both caustic soda and chlorine are essential basic chemicals that support modern society, deeply intertwined with the way we live today. Demand for these products and related businesses continue to expand generally in line with economic growth.

Asahi Kasei has earned a great deal of trust from customers during the half century since the commercial launch of this process in 1975. Due to its outstanding performance and reliability, our technology is now adopted at over 170 electrolysis plants in 30 countries around the world.

- *The ion-exchange membrane process for chlor-alkali electrolysis is one of Asahi Kasei’s “Environmental Contribution Products” which contribute to reducing the environmental burden throughout their complete lifecycle from raw material extraction to production, transportation, use, and disposal.

An ion-exchange membrane

An ion-exchange membrane Basic principle of the ion-exchange membrane process for chlor-alkali electrolysis

Basic principle of the ion-exchange membrane process for chlor-alkali electrolysis Electrolyzers utilizing the ion-exchange membrane process

Electrolyzers utilizing the ion-exchange membrane process

Not letting customers’ trust lead to complacency

The ion-exchange membrane & electrolysis system business has steadily grown by leveraging its strength of providing a one-stop solution that covers both essential products and after-sales support for the ion-exchange membrane process for chlor-alkali electrolysis. Nevertheless, electrolysis plants are highly sensitive to operating conditions such as electric current and temperature. Even slight variations can significantly affect power consumption and equipment lifespan. Although they had earned customer trust through a proven track record and excellent system performance, they felt that a new approach was required to meet emerging needs in terms of greater operational stability, more precise monitoring with IoT, and increased demand for sustainability. To heighten the business’s ability to support customers in their stable production of caustic soda and chlorine, and to ensure their continued supply for the future, Asahi Kasei acquired Recherche 2000 Inc. (R2), a provider of monitoring systems and advanced analytical software for the electrolysis field, and embarked on business model transformation.

A cross-functional project team was formed across the business to drive the transformation. They formulated a plan, and worked together to make proposals on issues that customers were presumed to have. Initially, the goal was a full transition to a solution-oriented business model. However, early feedback was disappointing, with some customers saying “although the concept seems good, your ideas don’t match the situation at the plant.” Team leader Shuta Kojima kept trying to find a way to overcome the gap between the ideal and reality. Instead of a fully solution-oriented model, he suggested combining Asahi Kasei’s traditional product-based offering with value-added services that bring out the full potential of its products. This led to a more practical and effective model.

Kenji Onaka of the Marketing Department was the liaison between Asahi Kasei and R2 to support the technical aspects of the transformation. “R2 provides advanced monitoring systems for electrolysis plants, enabling predictive maintenance and production optimization. Although there are many monitoring solution providers around the world, few specialize in electrolysis. R2’s data science expertise to provide detailed analysis through software is truly exceptional. We developed services and applications that maximize the value of R2’s strengths as part of our business.” Onaka led system development to ensure full realization of synergy between Asahi Kasei and R2.

Shuta Kojima of the Marketing Department

Shuta Kojima of the Marketing Department Kenji Onaka of the Marketing Department

Kenji Onaka of the Marketing Department

Customer-orientation as a team

To refine the business model, Tetsuya Suwa of the Customer Success Department asked customers what they thought about introducing new monitoring devices and systems. The feedback he received was not encouraging. “We don’t want a complicated system to detect problems. If you make it with a single button that ensures stable operation, we might be interested.” Though the feedback was frustrating, it did indicate customers’ confidence in Asahi Kasei’s products and services. “I told Kojima and Onaka that we should fully support stable operation by customers as part of our one-stop solution offering. I thought we needed to achieve even greater operational stability by customers through centralized monitoring and data analysis.” Kojima and Onaka worked on how the monitoring devices and systems should be offered based on customer input through their colleagues.

Tetsuya Suwa of the Customer Success Department

Tetsuya Suwa of the Customer Success Department

Conveying proposals more clearly

By speaking with customers worldwide, they found it difficult to effectively convey the value and vision of the new business model in a clear and concise manner. Kojima realized that it wasn’t enough just to add new software and services to the established one-stop offerings of electrolyzers, electrodes, ion-exchange membranes, process design, and technical support. They needed a framework to propose tailored solutions from this comprehensive lineup that not only meet specific customer challenges but also maximize the value of the purchased products. This new business approach was launched under the brand “AlkaNexus.”

The brand logo for “AlkaNexus,” combining “alka” for chlor-alkali and “nexus” meaning connection. The brand name is inspired by a strong determination to deliver chlor-alkali solutions that bring customers, markets, and the world together.

Building new relationships through patient dialogue

Even after launching the AlkaNexus business model and brand, it was difficult to convince customers to adopt new solutions. Understanding the benefits is one thing, deciding to use them is another. Most customers follow a regular replacement cycle for ion-exchange membranes and electrodes every few years. As long as they can continue producing caustic soda and chlorine with predictable replacement costs, there is little incentive for them to allocate additional budget for monitoring and data analytics technology.

While making proposals to customers, sales representative Taisuke Nakamura realized that gaining understanding was not enough. Customers needed to see the new functions in person. He organized tours for customers to visit plants with the monitoring system installed, allowing them to directly hear from actual users. By sharing actual examples, he hoped they would more positively view the value of making operations even safer and more stable. After nearly a year of persistent effort, he got a new customer to adopt the AlkaNexus solution. It was a big accomplishment for Nakamura, as was able to build a new relationship with a customer that had not previously used Asahi Kasei’s ion-exchange membranes.

Taisuke Nakamura of the Sales Department

Taisuke Nakamura of the Sales Department

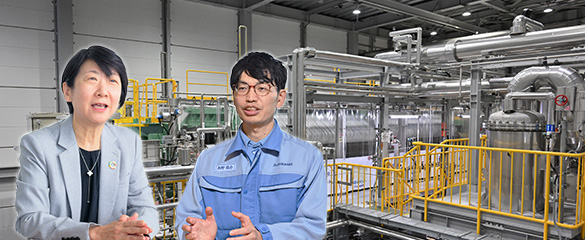

Enhancing technical development through data collection

The monitoring and data analysis technologies developed by R2 are also being integrated into new product developments. Yu Endo of the Ion Exchange Membrane Research & Development Department says global adoption of the new one-stop solution will not only enhance operational stability but also drive further innovation in technology development. “Operating conditions vary across countries depending on factors such as salt composition and electricity costs. If we can access and analyze this data through expanded monitoring and analytics, we will be able to improve our development of membranes, electrodes, and electrolyzers even further. Looking at real customer data also gives us a fresh mindset, allowing us to develop with greater flexibility and a stronger customer focus.” Being connected with plants around the world through data will drive the next evolution in technological development.

Yu Endo of the Ion Exchange Membrane Research & Development Department

Yu Endo of the Ion Exchange Membrane Research & Development Department

The challenge continues

A new customer portal site was launched to enable customers to respond quickly to potential issues on their own. The portal features a knowledge hub with comprehensive technical resources and a user-friendly diagnostic app for assessing membrane condition. Customer support was also expanded with resource recycling services for electrolysis cells and electrodes, contributing to sustainability.

What lies ahead for AlkaNexus? Kojima’s vision is filled with possibilities and ambition. “First, I would like to expand the new one-stop solutions through AlkaNexus to further contribute to our customers’ business success. Looking ahead, we can use Asahi Kasei’s data and expertise to address larger chlor-alkaline industry challenges including carbon neutrality and efficient use of precious metals.”

Building on the knowledge and expertise cultivated over half a century, and the trust they earned from their customers, they will not only to sell products but also address the challenges facing the industry and society. The ion-exchange membrane & electrolysis system business is already taking steps toward the next 50 years.

- Note:Titles and contents are current as of the interview date.

Related information

Other stories

High ionic conductive electrolyte for next-generation batteries: Business advancement and market development through co-creation

High ionic conductive electrolyte for next-generation batteries: Business advancement and market development through co-creation The Road to Solvent ZERO

The Road to Solvent ZERO Be a Connector: A New Site for Co-Creation in the Semiconductor Business

Be a Connector: A New Site for Co-Creation in the Semiconductor Business Pioneering the future of mobility through semiconductors

Pioneering the future of mobility through semiconductors From Fashion to Medical Care: How Asahi Kasei’s Core Technologies and Innovations Drive the Evolution of Business

From Fashion to Medical Care: How Asahi Kasei’s Core Technologies and Innovations Drive the Evolution of Business Asahi Kasei’s Ideal Hydrogen Society and World-leading Hydrogen Production Technology

Asahi Kasei’s Ideal Hydrogen Society and World-leading Hydrogen Production Technology The Asahi Kasei Judo Team Holds Workshops That Convey World-Class Spirit and Techniques to Future Generations

The Asahi Kasei Judo Team Holds Workshops That Convey World-Class Spirit and Techniques to Future Generations Asahi Kasei's Track Team Brings a Community Together Through a Passion for Sports

Asahi Kasei's Track Team Brings a Community Together Through a Passion for Sports