Receipt of the Imperial Invention Prize for technology using nickel to extend electrode service life

Contributing to the stable operation of chlor-alkali electrolysis process that supports the infrastructure of daily life and society

May 27, 2025

Asahi Kasei Corp.

Asahi Kasei has received with the 2025 Imperial Invention Prize, the highest award to be presented at the 2025 National Commendation for Invention by the Japan Institute of Invention and Innovation, for invention of technology using nickel to extend electrode service life (patent no. 6120804, “the Invention”). In connection with this award, Asahi Kasei has also received the Award for Distinguished Contribution for Driving the Invention into Implementation.

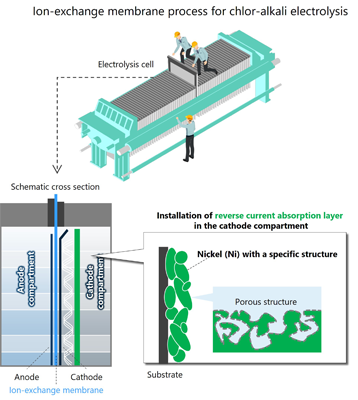

Ion-exchange membrane process for chlor-alkali electrolysis

Ion-exchange membrane process for chlor-alkali electrolysis

The Invention is recognized for suppressing the deterioration of the electrodes used in the ion-exchange membrane process for chlor-alkali electrolysis (“the Process”), which enables long-term, stable operation. The Process produces chlorine, caustic soda (sodium hydroxide), and hydrogen through the electrolysis of brine. Since being commercialized by Asahi Kasei in 1975, the Process has been adopted at over 160 plants in more than 30 countries worldwide (as of December 2024) by leveraging the company’s extensive experience over 50 years, and ability to supply a wide range of technology required for chlor-alkali electrolysis including materials, design, and operational support as a one-stop solution provider.

In operating the Process, when electrolysis is stopped due to temporary reductions in demand for chlorine and caustic soda, equipment malfunctions, power outages, etc., the electrodes (especially the cathode) deteriorate due to reverse current1, leading to problems such as increased power consumption with a rise in electrolysis voltage and shortened cathode service life, thereby hindering stable operation.

To suppress such reverse current, conventional measures have used mechanical equipment. However, this approach is susceptible to malfunctions and operator errors, making it difficult to completely avoid cathode deterioration. As such, a fundamental solution that does not rely on mechanical equipment has long been sought after.

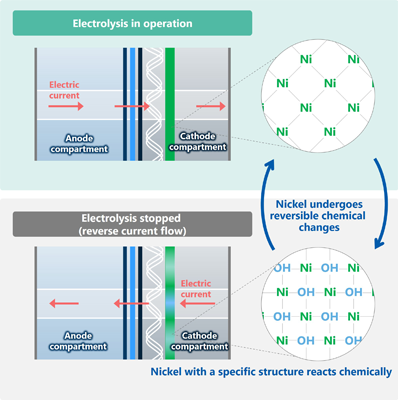

The Invention is based on a completely different concept to eliminate the need for mechanical equipment. By installing nickel with a porous structure as a reverse current absorption layer in the electrolysis equipment, it utilizes a chemical reaction of nickel to neutralize the effect of reverse current on the cathode. Cathode degradation progresses after the cathode potential reaches a certain level due to the reverse current that occurs when electrolysis is stopped. In theory, it was known that installing an element that undergoes a chemical reaction at a potential lower than said certain level could be a way to prevent the potential within the electrolytic cell from reaching the certain level, but this had not been applied in practice due to technical challenges.

The characteristic of the Invention is that it specifies the structure of a reverse current absorption layer that provides stable function over a long period of time while clarifying the method for realizing it under industrial conditions. The reverse current absorption layer must overcome the trade-off between being porous and having high strength, while having processability on large areas. Commercialization was successfully achieved by overcoming the issues thorugh the application of thermal spraying2. As the reverse current absorption layer formed by thermal spraying undergoes a reversible chemical reaction with nickel, the reverse current absorption function is not diminished even if electrolysis is stopped and restarted multiple times, enabling continuous protection of the cathode.

Conceptual diagram of nickel with a specific structure

Conceptual diagram of nickel with a specific structure Conceptual diagram of the chemical reaction of nickel during electrolysis and when stopped

Conceptual diagram of the chemical reaction of nickel during electrolysis and when stopped

Chlor-alkali electrolysis equipment incorporating the Invention has been sold to chemical manufacturers around the world, contributing to the stable production of chlorine and caustic soda which support the lives of people worldwide. Adoption of such equipment is expected to expand further. Asahi Kasei is also investigating the applicability of the technology of the Invention to other electrolysis processes such as alkaline water electrolysis for green hydrogen production.

- The Imperial Invention Prize

- Akiyasu Funakawa

General Manager

Ion Exchange Membrane Research & Development Dept.

Ion Exchange Membrane & Electrolysis System Division

Asahi Kasei Corp.

Toshinori Hachiya

General Manager

Microza & Water Processing Quality Assurance Dept.

Microza & Water Processing Division

Asahi Kasei Corp. - Award for Distinguished Contribution for Driving the Invention into Implementation

- Koshiro Kudo

President and Representative Director

Asahi Kasei Corp.

(affiliations current as of the date of the award) - Comment from Akiyasu Funakawa:

- Chlorine and caustic soda are indispensable raw materials that form the basis of various products which support our daily lives. This prize is a great encouragement as I continue to work on developing electrolysis technology that contributes to the world.

- Comment from Toshinori Hachiya:

- In response to customer troubles, we have faced many issues and worked with many members to devise ideas. I am very happy that the results of our persistent efforts have been recognized in this way.

- 1A current that flows in the opposite direction to the normal flow when electrolysis is stopped, etc., causing deterioration of electrodes and dissolution of the catalyst.

- 2A surface treatment technology that involves heating a material to a molten or near-molten state and spraying it onto a surface to form a coating. This technology can be adopted for a wide range of applications as it can be used for processing large-area substrates.