The Asahi Kasei Group's Environmental Contribution Products

What are Environmental Contribution Products?

The Asahi Kasei Group internally certifies products and services that contribute to improving the environment and reducing the environmental impacts along their overall lifecycle as Environmental Contribution Products.

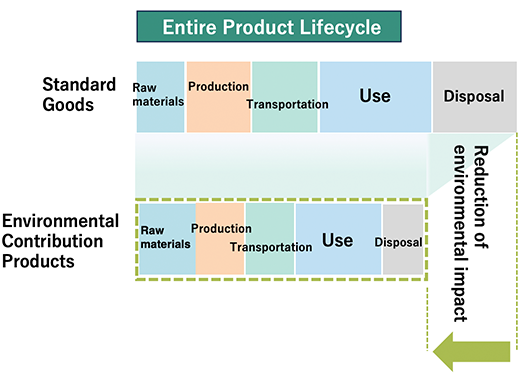

Conceptual diagram of Environmental Contribution Products and amount of environmental contribution

Environmental Contribution Products are evaluated at each stage from collection of raw materials to production, transportation, use, and disposal.

During the evaluation, we compare them to standard products on the market or our conventional products (as a baseline) to confirm whether or not they have reduced the overall environmental impacts.

Even if there is a high environmental impact at one of the stages, if they reduce the impacts over the entire lifecycle, we still certify them as Environmental Contribution Products.

We proactively implement these efforts because we believe they can contribute to reducing the environmental impacts on society overall.

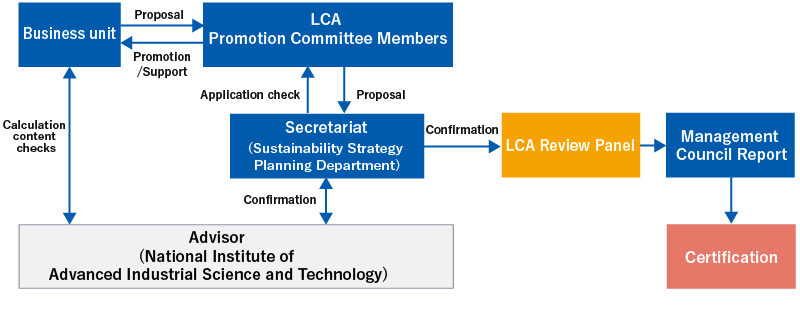

The calculation for the amount of environmental contribution from Environmental Contribution Products is based on our internally-formulated “Guidelines for Environmental Contribution Products” which references various guidelines published by The Institute of Life Cycle Assessment, Japan, the Japan Chemical Industry Association, the Ministry of Economy, Trade and Industry, and the World Business Council for Sustainable Development (WBCSD), for example. We utilize external databases such as the LCA (lifecycle assessment) database “IDEA” provided by the National Institute of Advanced Industrial Science and Technology (AIST) for use in calculations such as for the amount of environmental contribution.

Targets and results

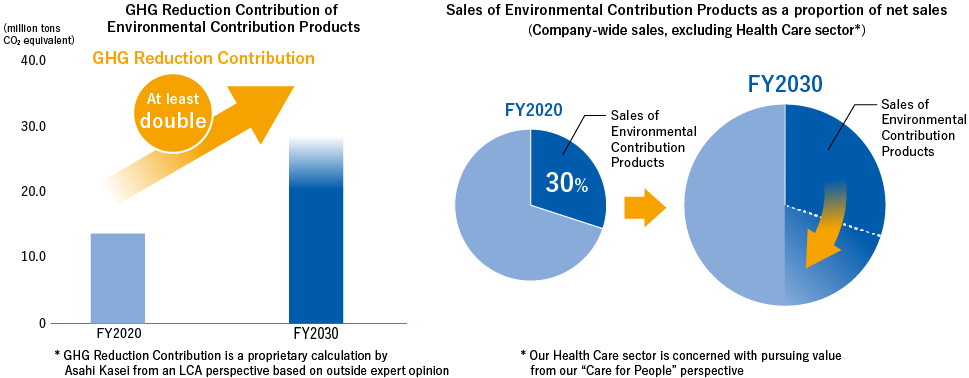

The Asahi Kasei Group aims to contribute to reducing GHG emissions in society as a whole by expanding GHG reduction contribution through Environmental Contribution Products.

We set specific targets for GHG reduction contribution to increase by at least double in fiscal 2030 and by 2.5 times or more in fiscal 2035 compared to fiscal 2020.

Up to this point, we have certified 26 products as Environmental Contribution Products, and GHG reduction contribution for fiscal 2024 was 1.51 times that of fiscal 2020.

We will continue enlarging our environmental contributions through business by engaging in research and development that focuses even more heavily on environmental contribution.

Contribution to reducing GHG emissions through Environmental Contribution Products

Trends and Targets in GHG Reduction Contribution (Indexed with Fiscal 2020 as 100)

Trends and Targets in GHG Reduction Contribution (Indexed with Fiscal 2020 as 100)

Fiscal 2024 reduction contribution as a reference value: approx. 19.50 million tons CO2-equivalent*

- *Baselines and the approach for the relative contribution ratio are established separately for each respective product as deemed appropriate based on the perspective of internal management.

Therefore, please bear in mind that the above values are simple totals of the contribution amount for each product, and are rational only under a certain set of conditions (and not suitable for comparisons with other companies).

New establishment of Next Environmental Contribution Products Candidates

Beginning in fiscal 2024, our company has established a new framework called “Next Environmental Contribution Products Candidates”, as we work towards early evaluation and visualization of environmental contribution (such as GHG reduction contribution) for technologies and product ideas that are at the research and development stage but could become Environmental Contribution Products in the future.

By adopting a LCA viewpoint starting at the stage of research and development, we aim to enable quantitative evaluation of environmental impact at each stage, from design to material selection and process building, leading to smooth post-market certification and creation of environmental value.

Internal Certification Process

Products proposed by each business are internally certified as Environmental Contribution Products after external experts on the LCA Review Panel confirm the rationality of the environmental contribution from an LCA perspective. The inclusion of academic perspectives has promoted the improvement of the knowledge and skills of our human resources and has also led to a deeper understanding of the need to promote initiatives for Environmental Contribution Products with a medium- to long-term perspective.

LCA Review Panel (held on June 26, 2025)

- Chair

- Hiroyuki Uchida (Principal, Mizuho Research & Technologies, Ltd.)

- Panel Members

- Keigo Matsuda (Professor, Nagoya University)

Kensuke Kobayashi (Associate professor, Prefectural University of Hiroshima)

At the LCA Review Panel, personnel in charge of each product explain the details of environmental contributions and receive comments and advice from outside experts on the suitability of the establishment of baselines and our approach to environmental contribution.

External expert Hiroyuki Uchida (Principal, Mizuho Research & Technologies, Ltd.)

The importance of reduction contribution and Environmental Contribution Products is increasing more than ever as an initiative that aligns corporate growth with GHG emission reductions.

On the other hand, if the calculation method is incorrect, there is a risk of causing misunderstandings in society and not producing accurate GHG emission reductions.

I commend Asahi Kasei’s sincere efforts to reduce GHG emissions, including calculations based on major guiding documents, reviews by external experts, and disclosure of the process.

I look forward to the company’s continued efforts to achieve its targets for 2030 and 2035 under appropriate management.

Note: Titles, etc. are current as of the time of publication

Description of Environmental Contribution Products

・Saving resources by integrating functions

・Increasing the usage rate of recycled PET and reduction of solvents (DMF)

・Increasing the usage rate of recycled material

Dimethyl carbonate production process using CO2 as a raw material

Dimethyl carbonate production process using CO2 as a raw material・CO2 as a raw material

-

Polycarbonate production process using CO2 as a raw material

Polycarbonate production process using CO2 as a raw material・CO2 as a raw material

・High efficiency in N2O decomposition

・High yield

・High yield (catalysts)

-

Lithium-ion battery (LIB) separators

・Essential for LIBs in electric vehicles

Ion-exchange membrane process

Ion-exchange membrane process

for chlor-alkali electrolysis・Low electricity consumption in electrolysis

Filtration membrane Microza™

Filtration membrane Microza™・High durability of membrane

(resource-saving) / reuse of water resources CO2 sensors

CO2 sensors・Optimization of ventilation

Current sensor (components for large air conditioners)

Current sensor (components for large air conditioners)・Energy conservation with inverter motors

Hall elements and Hall ICs (components for home air conditioners)

Hall elements and Hall ICs (components for home air conditioners)・Energy conservation with inverter motors

ICs2 for temperature-compensated crystal oscillators (TCXO) for communication base stations

ICs2 for temperature-compensated crystal oscillators (TCXO) for communication base stations・Reduction of electricity consumption due to absence of heater

Hebel Haus™ unit homes

Hebel Haus™ unit homes・Durability for 60 to 100 years / ZEH etc., energy conservation

Hebel Maison™ apartment buildings

Hebel Maison™ apartment buildings・Durability for 60 to 100 years / ZEH etc., energy conservation

Neoma Foam™ insulation material

Neoma Foam™ insulation material・Energy-saving through advanced thermal insulation performance

AWP™ photosensitive resin for printing plates

AWP™ photosensitive resin for printing plates・High printing performance, productivity, no solvent required

UVC LEDs for water sterilization

UVC LEDs for water sterilization・Low electricity consumption and no use of mercury

Asaclean™ purging compound

Asaclean™ purging compound・Resource saving in the cleaning of molding machines

S-SBR synthetic rubber for fuel-efficient tires

S-SBR synthetic rubber for fuel-efficient tires・Contribution to tires’ rolling performance

Elastomer for asphalt modification

Elastomer for asphalt modification・Improvement of road durability

Modified PPE Xyron™ (solar cell connector material)

Modified PPE Xyron™ (solar cell connector material)・Reduction in the number of modules required for high-voltage systems and the quantity of resin used

HDI-based polyisocyanate Duranate™ low viscosity grade

HDI-based polyisocyanate Duranate™ low viscosity grade・Reduction in solvent use for paint manufacturers

Duranol™ polycarbonatediol for soft feel paint

Duranol™ polycarbonatediol for soft feel paint・Reduction in solvent use (butyl acetate)

Modified PPE Xyron™ (automotive secondary battery component)

Modified PPE Xyron™ (automotive secondary battery component)・Weight saving of battery cases in hybrid vehicles

- 1Photo shows a camera module for a smartphone in which the lens controller IC is built-in.

- 2Photo shows a wafer of ICs for TCXO