Pollution Prevention and Resource Circulation

Policy

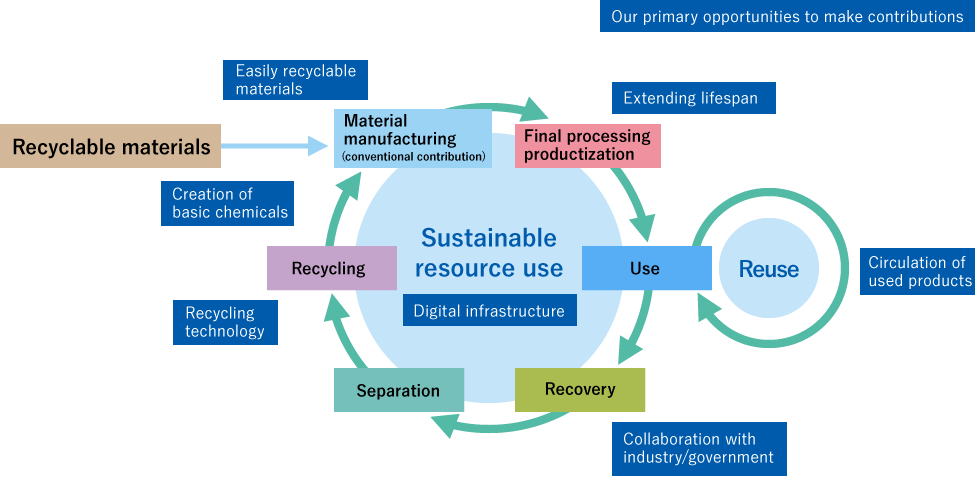

“Building a circular economy” is a major plank of the Asahi Kasei Group's Global Environmental Policy and “Circular Economy” is included in our materiality. We work to efficiently utilize resources and energy and to reduce the environmental impact throughout the entire life cycle in our business activities. In order to contribute to a circular economy, we have worked to reduce industrial waste, reduce the impact of chemical substances, prevent air and water pollution, and use resources effectively.

In addition, we will continue to contribute to building a circular economy, as we established it as one of the issues we will work on to achieve our vision for 2030 in the Medium-term Management Plan “Trailblaze Together” for fiscal 2025–2027.

- Sustainability Management > Asahi Kasei Group's Materiality > Materiality List

- Sustainability Vision - Asahi Kasei Group Vision > Sustainability with a View Toward 2050

Reduction of industrial waste and promotion of recycling

As well as working to reduce the amount of industrial waste through the 3Rs of reduce, reuse, and recycle, the Asahi Kasei Group is also working on renewables.

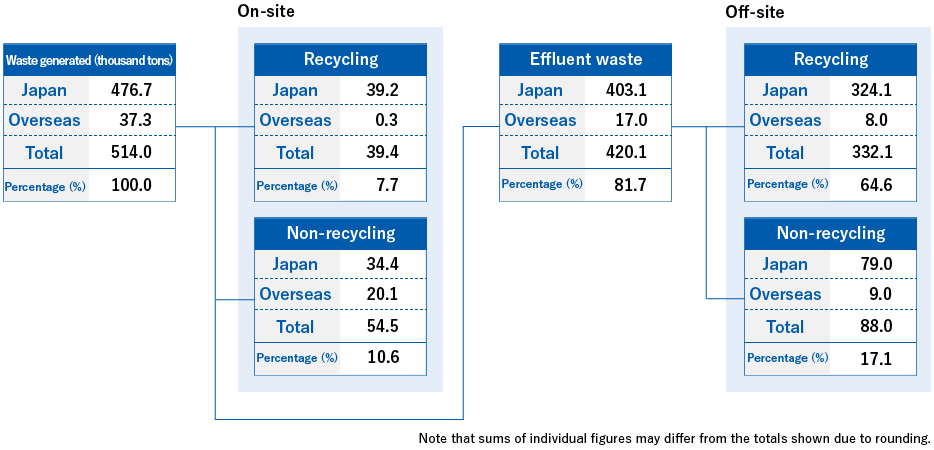

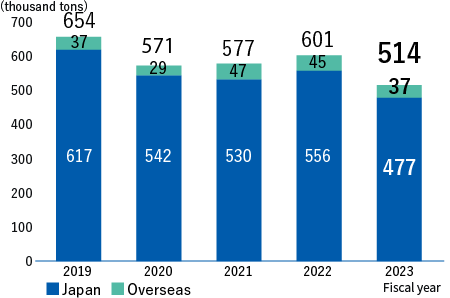

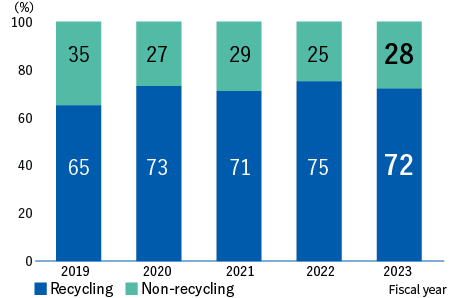

The amount of industrial waste generated by the Asahi Kasei Group (Japan and overseas) in fiscal 2024 was 559.1 thousand tons, of which 19.9 thousand tons was specially managed industrial waste. Additionally, the industrial waste recycling rate1 was 72.5%, and the non-recycling rate2 was 27.5% (of which the heat recovery rate was 20.6%). So that we can continue to recycle in the future, we will keep on taking steps to separate waste and search for processing sites where waste can be recycled.

We are also promoting initiatives to suppress emissions of waste plastic and to increase the recycling rate. The volume of waste plastic emitted in fiscal 2024 in Japan was 19.4 thousand tons (a 4.9% reduction year on year) and the recycling rate was 45.1% (a 1.8% reduction from the previous fiscal year). To suppress emissions, we are advancing initiatives to increase unit consumption (reducing emission of unnecessary scraps) and to turn emitted plastic into valuable articles (such as raw materials). With respect to recycling initiatives, we are subcontracting the disposal of waste to recyclers of waste plastic with material and chemical recycling capabilities. Going forward, we will continue our initiatives to suppress waste plastic emissions and to recycle.

The Asahi Kasei Group has been working toward the goal3 of reducing landfill waste plastic in Japan to zero. Because temporary construction waste could not be effectively used, the amount of waste plastic sent to landfill in fiscal 2024 was 4.5 tons, missing the target. We are continuing our initiatives toward zero landfill waste plastic.

Regarding PCB4 waste, we are systematically moving forward with proper management and disposal within the disposal timeframe.

We enhanced our daily management of off-site treatment of industrial waste by expanding the use of electronic manifests. We also performed periodic on-site inspections of consigned firms to ensure that proper treatment is performed by industrial waste collection, transportation, and processing contractors in accordance with sound systems of control.

- 1Recycling ratePercentage of chemical recycling and material recycling

- 2Non-recycling ratePercentage of heat recovery, weight reduction, and landfill disposal

- 3Target of reaching zero landfill waste plasticExcluding waste plastic generated by the homes business

- 4PCBs (polychlorinated biphenyls) are persistent and pose a risk to the living environment and human health. Their manufacture and use are essentially prohibited in Japan.

FY2024 flow of industrial waste*

FY2024 flow of industrial waste*

Waste generated

Waste generated Recycling rate

Recycling rate- *Transformation into solid fuel and raw fuel was classified as recycling (material recycling) between fiscal 2020 and fiscal 2021.

From fiscal 2022 onward, it has been classified as non-recycling (heat recovery).

- *Transformation into solid fuel and raw fuel was classified as recycling (material recycling) between fiscal 2020 and fiscal 2021.

Reducing industrial waste from construction materials and homes businesses

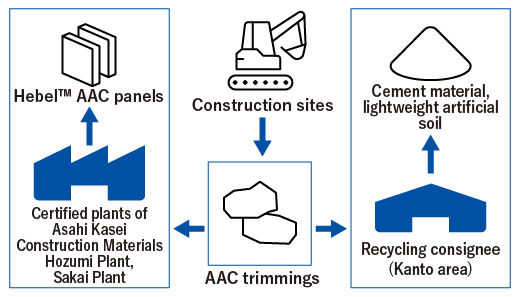

In the construction materials business, Asahi Kasei Construction Materials collects and recycles Hebel™ autoclaved aerated concrete (AAC) panels in its own plants, utilizing its certification for "wide-area recycling"1. Asahi Kasei Homes is also reducing the volume of waste as well as implementing sorted waste collection at housing construction sites. With these measures, waste for final disposal has been reduced to zero at new construction sites.

Recycle flow for trimmings of Hebel™ AAC panels

Recycle flow for trimmings of Hebel™ AAC panels

- 1Certification for wide-area recyclingFor certain parties, who perform recycling in a wide-area, Japan's Minister of the Environment eliminates the need to obtain separate waste transport permits for each local area. The system was established to promote further recycling of industrial waste.

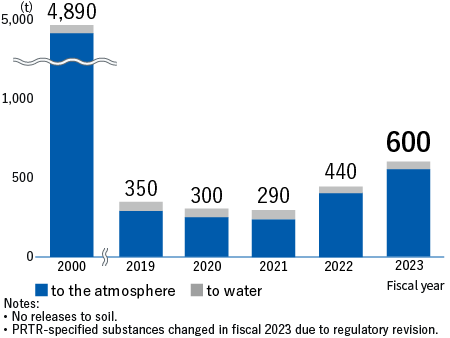

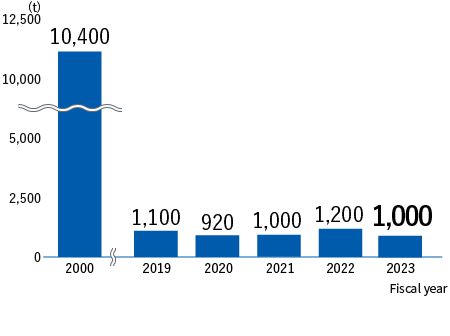

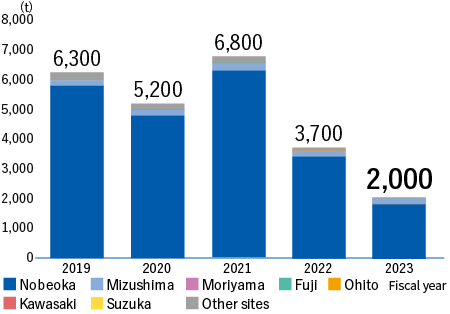

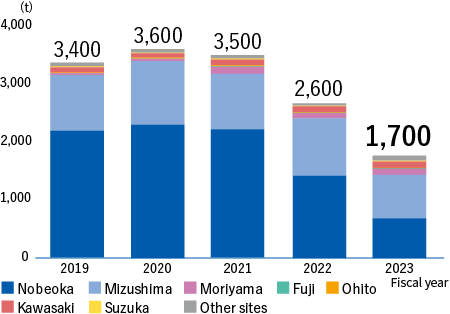

Reducing emissions of chemical substances

The Asahi Kasei Group works to reduce the release of chemicals substances specified in the PRTR1 Law and other chemical substances which we have voluntarily designated for reduction with priority based on the degree of hazardousness and amount of release. As shown in the graphs below, releases of PRTR-specified substances and VOC2 emissions were reduced by 91% and 92%, respectively from fiscal 2000. We will continue to enhance control of operation and equipment to prevent any accidental release.

Releases of PRTR-specified substances

Releases of PRTR-specified substances Releases of VOCs

Releases of VOCs

- 1PRTRPollutant release and transfer register. Under the PRTR Law, releases to the environment and off-site transfers of specific hazardous chemical substances must be monitored and recorded for each production facility and operating site. Results are reported to the government, which publishes aggregated results.

- 2VOCVolatile organic compound. Although the term generally applies to any organic compound which is in gaseous state at the time of release, regulations for the control of their release exclude methane and some fluorocarbons which do not form oxidants.

Initiatives to suppress emissions of fluorocarbons

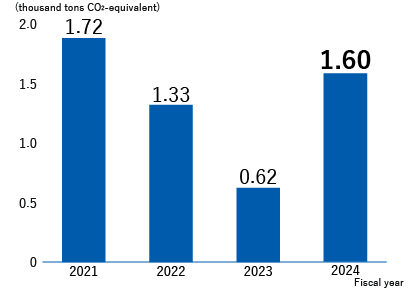

In accordance with the Act on Rational Use and Appropriate Management of Fluorocarbons, we are working to properly maintain equipment and facilities subject to the act and to take measures to prevent leakage of fluorocarbons. The Asahi Kasei Group is advancing with deployment of the Refrigerant Management System (RaMS), as we work towards proper management including simple and regular inspections of legally-subject equipment. Our company’s individual calculated volume* of fluorocarbon leakage in fiscal 2024 was 972.3 tons of CO2-equivalent. Also, the Asahi Kasei Group’s total calculated volume of fluorocarbon leakage was 1602.7 tons of CO2-equivalent.

In the future, we will continue to take measures to prevent leakage of fluorocarbons.

- *Calculated volume of fluorocarbon leakageVolume of fluorocarbon leakage calculated based on filling and recovery certificates, in case of fluorocarbon filling and recovery during equipment maintenance.

Asahi Kasei Group (Japan) fluorocarbon leakage volume

Asahi Kasei Group (Japan) fluorocarbon leakage volume

Preventing air pollution

The Asahi Kasei Group works to control emissions and prevent leakage in order to avoid the pollution of air, water, soil, and groundwater. Measures to prevent noxious odors include the installation of exhaust gas absorption equipment and increasing the capacity of our wastewater treatment facilities. To prevent soil pollution, we perform tests and take appropriate measures in accordance with the Soil Contamination Countermeasures Act and related regulations. Substances covered by the Air Pollution Control Act are managed within regulatory standards on a continuing basis.

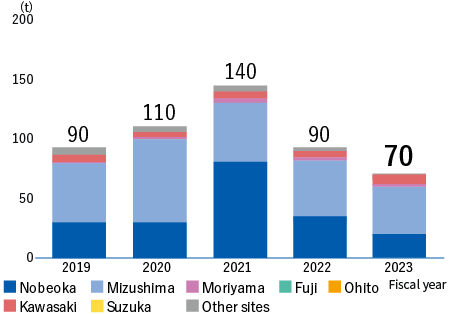

SOx emissions

SOx emissions NOx emissions

NOx emissions

Soot and dust emissions

Soot and dust emissions

Policy

The Asahi Kasei Group will promote the reduction of environmental impacts and the efficient utilization of resources and energy throughout their entire life cycle in its business activities in order to contribute to a circular economy.

Specifically, it will promote the 3Rs of Reduce, Reuse, and Recycle, and increase the usage of resources and energy with lower environmental impacts as well as renewable resources and energy.

Asahi Kasei Group initiatives

We are working to recycle used plastics, use biomass raw materials , extend the service lifespan of our products, and improve their recyclability.

Targets of resource circulation

The Asahi Kasei Group has established the following targets, and has joined and discloses information through the Circular Partners (CPs) established, managed, and operated by the Ministry of Economy, Trade and Industry.

| Item | Value | Unit | Achievement timeframe |

|---|---|---|---|

| 1. Number of companies adopting the ion-exchange membrane process for chlor-alkali electrolysis cell rental service | 10 | Companies | Fiscal 2027 |

| 2. Rate of long-term periodic inspections conducted for Hebel Haus™ unit homes and Hebel Maison™ low-rise apartment buildings | 70 | % | Fiscal 2025 |

Overview

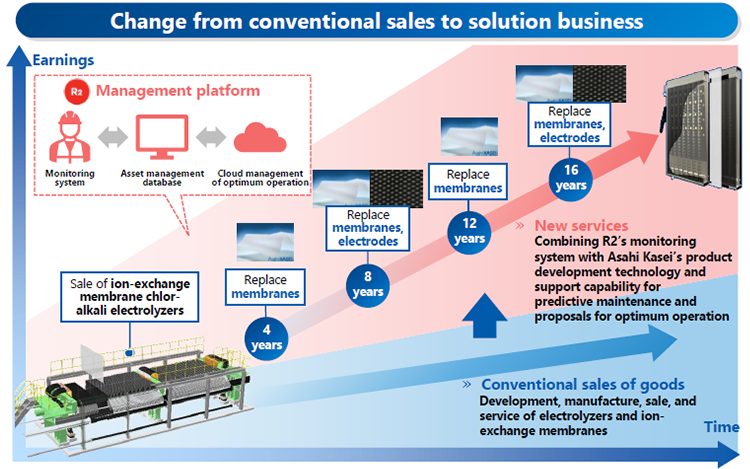

1. Formerly, customers of our chlor-alkali electrolysis process needed to keep spare cells for use during maintenance. Such spare cells tended to be idle assets when not in use. Our electrolysis cell rental service eliminates the need for each customer to keep spare cells themselves, and allows electrolysis cells to be effectively utilized within a region through reuse by multiple customers. This enables the 3Rs of Reduce, Reuse, and Recycle for the precious metals used in the electrolysis cells.

2. Asahi Kasei Homes provides Hebel Haus™ unit homes and Hebel Maison™ low-rise apartment buildings which have featured earthquake-resistant, fire-resistant, durable designs since the launch of its business. We have continued to pursue homes that allow long-term residency, with the “long-life home” strategy adopted in 1998, and “ALL for LONGLIFE” philosophy adopted in 2020. By managing clear indicators through the regular implementation of periodic inspections every 5 years for the first 30–60 years after construction, we are able to promote long-term use of products from the perspective of a circular economy, and also confirm the results of those efforts.

Examples of Initiatives

Ion-exchange process for chlor-alkali electrolysis

In our business of the ion-exchange process for chlor-alkali that sells systems for manufacturing the basic chemicals caustic soda and chlorine, we provide an electrolysis cell rental service that allows enhanced resource use rate and effective utilization of precious metals. We are also promoting systems for monitoring the operation conditions of customers’ electrolysis processes and making a transition from a conventional sales business to a solution business, as we aim to develop into a business conducive to a circular economy.

Homes business

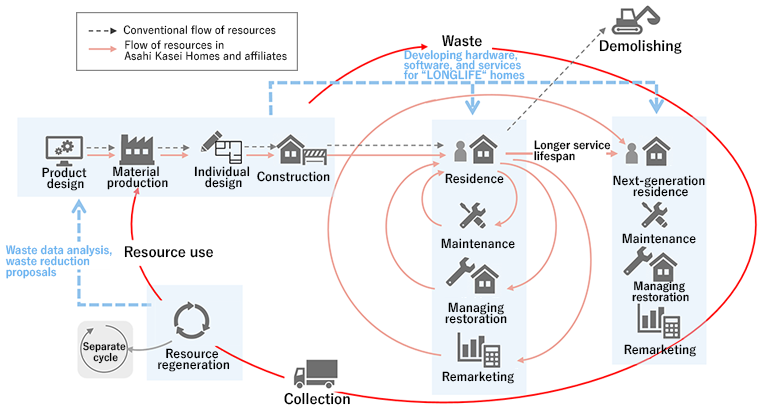

We provide long-life homes (products and services) conducive to the realization of a circular economy. In order to embody LONGLIFE, we have built a comprehensive system, including specification development that considers the lifecycle of homes, residence-specific design and construction, after-service featuring 60 years of free inspections, enhanced value-added for used homes, consulting during renovations and inheritance, and more. Through the functioning of this system with the help of customers and partner corporations, we enable circular use of homes that crosses generations.

Overview of the circular economy in Asahi Kasei Homes and affiliates

Overview of the circular economy in Asahi Kasei Homes and affiliates

We are also working on other initiatives aimed at achieving a circular economy from various perspectives, as we emphasize coordination with a diverse array of stakeholders, including universities, research organizations, and other companies, as well as coordination with national strategy. We established the Asahi Kasei-AIST Sustainable Polymer Coordination Research Laboratory with the aim of early realization of a social system that enables provision of sustainable polymers.

ISCC PLUS Certification* acquisition status

For the following products, we have acquired ISCC PLUS certification, which is an international certification system for sustainable products. Moving forward, we will continue to meet the expectations of society and our customers by offering products and services with sustainability-based qualities as we aim for a circular society.

- *ISCC (International Sustainability and Carbon Certification) PLUS certification

ISCC certification is an international certification for sustainability and carbon, and in particular, ISCC PLUS is a certification system that provides supply chain management and guarantees of primarily biomass and regenerated raw materials and products sold throughout the world.

| Product | Product name |

|---|---|

| Acrylonitrile (AN) | |

| Styrene monomer (SM) | |

| Cyclohexanol | |

| Cyclohexane | |

| Adipic acid, compd. with hexamethylenediamine | |

| Adipic acid | |

| Hexamethylenediamine | |

| Styrene-butadiene rubber (SBR) | Tufdene™ solution-polymerized SBR Asaprene™ solution-polymerized SBR |

| Butadiene rubber (BR) | Diene™ polybutadiene rubber Asaprene™ polybutadiene rubber |

| Thermoplastic elastomer (TPE) | Tufprene™, Asaprene™ T styrenic thermoplastic elastomer Tuftec™ hydrogenated styrenic thermoplastic elastomer S.O.E.™ hydrogenated styrenic thermoplastic elastomer |

| Polyethylene (PE) | Sunfine™ ultra high molecular weight polyethylene Suntec™ LD low-density polyethylene Suntec™ EVA ethylene-vinyl acetate copolymer Suntec™ HD and Creolex™ high-density polyethylene |

| Polyoxymethylene (POM) | Tenac™ polyacetal |

| Polyphenylene ether (PPE) | Xyron™ modified polyphenylene ether (mPPE) |