Process Safety

Policy

Based on the Group Mission of “contributing to life and living for people around the world,” the Asahi Kasei Group has established the ESH & QA and Health & Productivity Management Policy. This policy recognizes health, process safety, occupational health and safety, quality assurance, and environmental protection as top management priorities in all business activities, with consideration given to every stage of the product lifecycle, from R&D to disposal.

As a specific item regarding environmental safety, the policy clearly states that “we strive for stable and safe operation while preventing workplace accidents and securing the safety of personnel and members of the community.” In addition to full legal compliance, we proactively set our own targets and pursue continuous improvement. By actively disclosing information and maintaining open communication, we aim to foster public understanding and trust—principles that form the basic policies of our process safety initiatives.

Safety management for high pressure gas

At the Mizushima Works and Kawasaki Works, where large amounts of energy are consumed and various hazardous materials and high-pressure gases are handled, we place the highest priority on ensuring process safety. Both sites have obtained certification as Authorized Inspectors under Japan’s High Pressure Gas Safety Act. In addition to strict compliance with all relevant laws and regulations, we actively promote autonomous safety management in line with the certification system, striving to maintain safe and stable operations through advanced safety management practices.

In particular, the Mizushima Works was certified in fiscal 2021 as a Specially Certified Operator under the new certification program of the High Pressure Gas Safety Act, which recognizes sites that demonstrate exceptionally advanced safety initiatives. Furthermore, it has been recognized by the Ministry of Economy, Trade and Industry as a CBM*-applied facility—a status reserved for operators with the highest level of safety performance among other Specially Certified Operators.

- *Condition Based Maintenance (CBM)A maintenance approach in which maintenance plans are determined based on the actual condition of equipment.

| High Pressure Gas Safety Controller | Asahi Kasei Corp. President |

|---|---|

| High Pressure Gas Process Safety Division General Manager | Asahi Kasei Corp. Director and Primary Executive Officer |

| High Pressure Gas Process Safety Management Department General Manager | Asahi Kasei Corp. Senior General Manager of Corporate ESH |

Basic Policy for High Pressure Gas Safety

- Safety is an important fundamental of management, and all of our business activities depend on safety.

- Each one of our employees is responsible for safety, and safety is ensured by all employees together.

- We apply a PDCA (plan-do-check-act) cycle to continuously improve the level of safety.

- Measures to assess risks, and to eliminate and mitigate them, are persistent and ongoing.

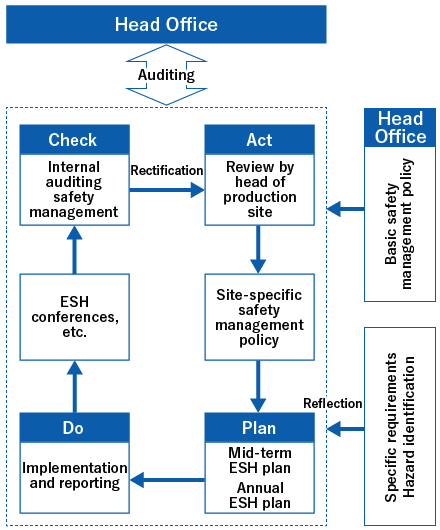

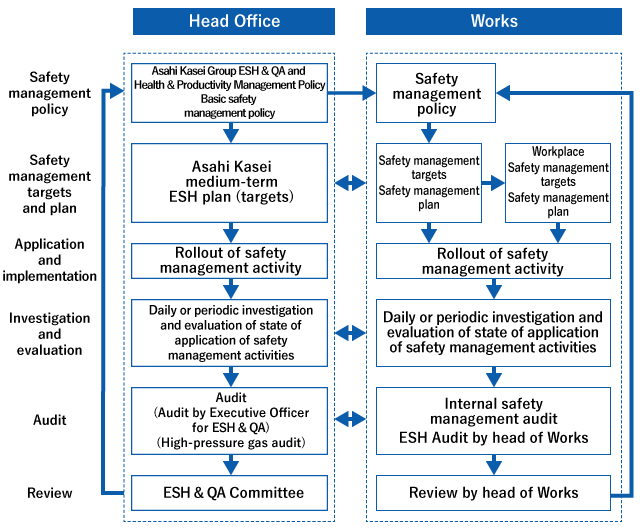

Under the basic policy for safety management established by the High Pressure Gas Process Safety Division General Manager, the High Pressure Gas Process Safety Management Department General Manager promotes the operation of the PDCA cycle and the process safety management system as shown in the diagram below. The High Pressure Gas Safety Controller bears overall responsibility for these activities.

PDCA cycle for safety management

PDCA cycle for safety management Process safety management system

Process safety management system

Process Safety and Disaster Prevention Performance and Accident Prevention Initiatives.

Process Safety and Disaster Prevention Performance in FY2024

In fiscal 2024, there were a total of three process safety-related incidents, consisting of one serious process safety accident and two process safety accidents. Although none involved severe events such as explosions or fires, an accident occurred at an overseas plant in which CO2 was accidentally released from a fire extinguishing system. In Japan, two leakage-related process safety accidents also occurred. For each of these incidents, an accident investigation committee or equivalent body was established to identify the root causes and implement preventive measures. The findings and lessons learned are being shared laterally throughout the company. With the goal of “never allowing a serious process safety accident to occur” in fiscal 2025, we will continue to engage in dialogue with on-site personnel at each location and plant to identify and address potential risks and issues, thereby further strengthening our process safety and disaster prevention capabilities.

[Number of process safety accidents in fiscal 2024]

- Number of serious process safety accidents: 1 (accident intensity of 18 points or more, or accident resulting in death)

- Number of process safety accidents: 2 (accident intensity of 3 points or more but less than 18 points)

- Number of minor process safety accidents: 21 (accident intensity of less than 3 points)

- Note: Classification by accident intensity is based on the standards of the Japan Petrochemical Industry Association (CCPS).

Preventing recurrence of accidents 1: Strengthening fire prevention and extinguishing measures for inside plant

In fiscal 2020 and fiscal 2022, plant fires occurred in Nobeoka City, Miyazaki Prefecture. In response, we established the Internal Standards for Fire Extinguishing Equipment in Indoor High Fire Risk Areas to ensure that similar incidents never happen again, and we are now implementing these standards across the entire Asahi Kasei Group. The standards identify high-risk areas for factory fires based on the following three perspectives:

- A

- Areas containing flammable materials that are easily ignited and generate high combustion heat

- B

- Areas where firefighting activities (by public fire departments) are difficult to perform

- C

- Areas where a fire could have a significant impact on production facilities, neighboring plants, or local residents if it spreads

We prioritize each of these areas and are working to strengthen systems for early fire detection, enhance fire prevention and extinguishing equipment capable of suppressing fires before they spread, and reinforce the organizational response structure needed to carry out effective initial firefighting.

In addition, cleanrooms—where smoke is purified and difficult to detect using standard smoke detectors—are now required to have ultra-high-sensitivity smoke detectors installed. By the end of fiscal 2024, 60% of the planned detector upgrades had been completed.

Preventing recurrence of accidents 2: Activities to hand down process safety technology

In chemical plants process safety management, it is important to avoid deviations from normal operating conditions and to ensure safe and stable operation. The Asahi Kasei Group carries out process safety risk assessments during plant construction and puts in place controls to prevent fires and explosions after the start of operation. We periodically inspect safety valves and interlock functions, properly maintain aging parts, and repeatedly review facilities and processes based on case studies of accidents both inside and outside the company.

In particular, in response to the so-called three major accidents that occurred outside the company in 2011, we began activities to hand down process safety technology in 2013. These activities involved identifying hazards in chemical plants, confirming preventive measures that may manifest as risks, handing down the details, and conducting training on them.

The activities consist of the following four steps:

- Step 1: Identification of hazard sources and assessment of hazard risks

- Step 2: Creation of technology transfer materials and succession of executive changes using summary materials

- Step 3: Training operators to use troubleshooting manuals, factor analysis, etc.

- Step 4: Training of operators with ability to apply knowledge to work through troubleshooting drills

Since fiscal 2022, this initiative has been expanded beyond chemical plants to include construction materials and textile plants where chemicals are not the final products. We identify plants that handle hazardous substances in their production processes and may experience abnormal reactions, then conduct risk assessments based on worst-case scenarios to clarify key management techniques that prevent accidents. To ensure these safety management techniques are accurately passed down to the next generation of supervisors and operators, we are revising and updating our technical documentation accordingly. Members of Corporate ESH and other specialists periodically review the content as third parties to ensure that no key perspectives are overlooked.

Preventing recurrence of accidents 3: Preventing accidental CO2 discharge from fire extinguishing systems

An accidental discharge of CO2 from a fire extinguishing system occurred at one of our overseas plants, reminding us once again of the potential danger such incidents pose to human health in case of malfunction. In response, we are currently inspecting all CO2 fire extinguishing systems installed at our plants both in Japan and overseas. Since the configuration of each CO2 system differs depending on the fire protection requirements of the facility, we are working with the respective plants to determine and implement measures that ensure effective fire suppression while eliminating risks to human safety.

Initiatives to Prevent Process Safety Accidents

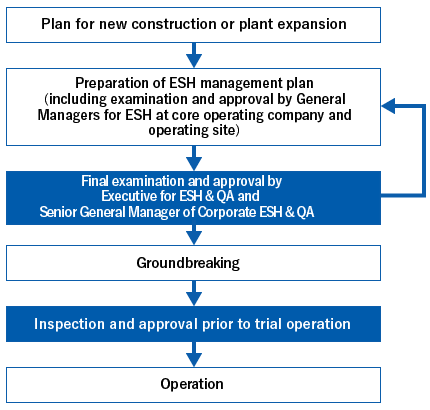

Pre-screening when investing in equipment

We perform process safety assessments before plant construction to ensure safety, not only when establishing new plants or expanding plants but also when modifying or dismantling plants. Based on our pre-inspection standards for capital investment, we conduct pre-installation safety inspections and pre-trial safety inspections before starting actual operation to confirm safety of new or modified equipment of a certain size or larger. The inspection system is also applied outside of Japan. Safety assessment is performed as part of the pre- inspection. Ranks are assigned based on the degree of hazard, with methods such as HAZOP* utilized in the risk assessment of high risk facilities.

- *

HAZOP :

“Hazard and Operability Study”

A method to identify causes of incidents and countermeasures based on assumptions due to deviations from the design. This highly exhaustive method is widely utilized throughout the process industries.

System for inspection prior to capital investment

System for inspection prior to capital investment

Measures for safe and stable production at plants

Given our diverse range of operations that include the Material, Homes, and Health Care business sectors, the Asahi Kasei Group has plants with a wide variety of different characteristics. A tailored approach is needed to ensure safety at all of these plants.

We employ a planned maintenance system to tailor the safety effort to each plant's specific requirements, including the use of the PDCA cycle. We have formulated separate maintenance standards for each plant of equipment to ensure the appropriateness of the method and period of maintenance as a feature of the planned maintenance system.

In addition, measures that span across the Asahi Kasei Group include a Maintenance Personnel Committee and group-wide plant engineering council with 4 specialist panels: Formulation of optimum systematic maintenance programs, establishment of standards and criteria, formulation of training systems for maintenance engineers, and sharing engineering information. We will ensure safe and stable production at our plants through these maintenance activities.

Training for process safety

At our petrochemical sites in Mizushima and Kawasaki, the Asahi Operation Academy (AOA) serves as the training center to cultivate the skills necessary to conduct production activities at petrochemical plants. AOA teaches the principles and structures of equipment, heightening the ability to identify the cause of equipment failure and to respond appropriately. Miniature plants and simulators are used at AOA to provide hands-on experience with controls and instrumentation. Operators thereby gain the technical skills and practical understanding of chemical engineering necessary for safe and reliable plant operation, with the ability to respond appropriately in the event of any abnormality.

In conjunction, we holds safety experiential training that allows employees to gain a firsthand understanding of the dangers of occupational accidents and the importance of safe operating standards. We carry out safety training exercises in which employees are given simulated experience of workplace dangers including being caught in/between machinery, contacting hazardous liquids, suffering a burn, tripping, falling on same level, or falling from height. In addition, we provide education on human behavioral tendencies and past accident cases to heighten safety awareness and foster personnel who consistently follow standards and rules while proactively avoiding danger.

We also incorporate VR experiences into our basic engineering education and safety training curriculum, and we are working to enhance training to improve risk sensitivity in equipment handling and operation.

| Regularly conducted training | Basic technology courses (machinery, instruments, electricity, and chemical engineering) First-hand safety course (getting caught/entangled, getting covered in liquid, burns, tripping, falling on same level, falling from height, etc.) Job level-based courses (problem-solving training, etc.) |

|---|---|

| Training target | Manufacturing operators and facility management personnel |

Emergency response

Disaster Prevention Drills

The Asahi Kasei Group has established and operates an emergency response system in accordance with internal regulations in preparation for the emergency such as a security accident or a large-scale earthquake. In our production areas, we have established a system to ensure smooth disaster prevention activities in order to ensure the safety of people and minimize the impact on surrounding areas in the event of an emergency. To this end, the plants have prepared an annual schedule and conduct regular disaster drills, and other activities.

These drills are designed to enable quick establishment of an emergency response system in the event of a fire or other abnormal situation, ensuring prompt initial response including firefighting. To further enhance initial firefighting capabilities, employees participate in internal and external competitions on rotation for testing various firefighting techniques. We have also introduced information and communication technologies to ensure swift coordination between on-site emergency response teams and the disaster response headquarters. In addition, we are improving the effectiveness of drills by expanding the assumed locations of incidents beyond factory premises to include research facilities and remote storage areas, ensuring that prompt and effective disaster mitigation actions can be taken regardless of where an emergency occurs.

Fire hydrant operation drill for new employees

Fire hydrant operation drill for new employees

Transportation and Distribution Safety

The Asahi Kasei Group is committed to preventing logistics accidents involving hazardous goods such as dangerous materials, toxic substances, and high-pressure gases. To further enhance logistics quality, we work closely with logistics companies entrusted with product storage, loading and unloading, and transportation operations. Together, we carry out a wide range of safety activities, including Logistics Safety Quality Conference, safety meetings, safety inspections, and product handling training sessions.

In fiscal 2024, in addition to the Logistics Safety Quality Conference attended by the President of Asahi Kasei to help raise safety awareness, we held multiple product-specific safety meetings that brought together many participants from across our logistics network.

Main activities in fiscal 2024

- Logistics Safety Quality Conference: 47 companies

- Safety meeting for hazardous goods: 33 companies, 48 participants

- Safety meeting for resin products: 17 companies, 44 participants

- Logistics safety inspections: 23 companies, 35 sites

- Product handling training: 11 items, cumulative 42 companies

In addition, we have introduced HAZMATers (Hazardous Materials Emergency Response Service), provided by the Maritime Disaster Prevention Center, to further strengthen our ability to respond to emergencies. The engagement of HAZMATers makes a highly specialized emergency response available 24 hours a day, 365 days a year, ensuring swift action by specialized personnel to prevent the spread of damage if an accident occurs.

[Number of logistics accidents in fiscal 2024]

| Target | Results | |

|---|---|---|

| Serious logistics accidents1 | 0 | 0 |

| Logistics accidents2 | 0 | 0 |

(Excluding certain subsidiaries and affiliates such as Asahi Kasei Homes)

- Definition of accidents

- 1Serious logistics accident: (1) One or more fatality or serious injury, (2) 100 million yen or more in damages, or (3) Significant social impact (resident evacuation notice, etc.)

- 2Logistics accident: (1) Personal injury (other than a serious logistics accident), (2) Public response (firefighting, leak prevention, etc.), (3) Explosion, spread of fire, poisoning, or risk of such accidents, or (4) 5 million yen or more in damages