Health & Productivity Management and Occupational Health & Safety

Policy

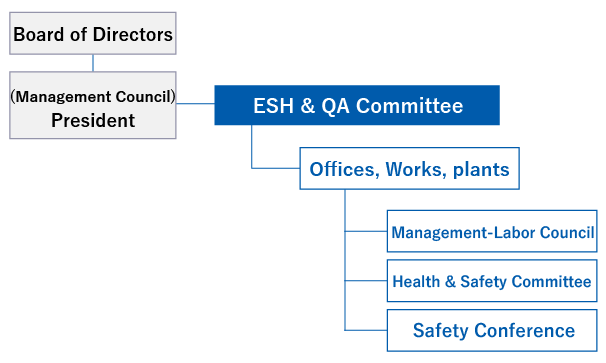

The Asahi Kasei Group promotes occupational health and safety based on the company policy of “giving the utmost consideration to health maintenance, operational safety, occupational health and safety, quality assurance, and environmental protection throughout the product lifecycle from R&D to disposal as preeminent management tasks in all operations.” Management and labor cooperate through Management-Labor Council and Health & Safety Committee established at each office, Works and plant, as we work on creating a company-wide environment where all employees can work at the Asahi Kasei Group in safety and health. At each production site, we hold Safety Conferences with cooperating companies for the purpose of preventing accidents and disasters, as we promote the formation of a safe and healthy workplace for all stakeholders. In addition, management holds an annual environment, safety and health audit, implemented with a focus on priority audit items defined in advance. They visit each production site and core operating company to implement the audit, while also engaging in dialogue to confirm the efficacy of activities.

Employee participation in improving health and safety

At the Asahi Kasei Group, management and labor cooperate in discussions related to occupational health and safety. At Management-Labor Council meetings, the labor union acts as a representative of the employees, and engages in discussions with management about health and safety. Discussions with management are held at every level, from workplace units to a company-wide unit, where their respective issues and efforts leading to solutions are discussed. In addition, reports are given and discussions are held at monthly meetings of the Health & Safety Committee, which are composed of personnel in charge at each site (Senior General Manager, General Manager, etc.), and labor unions.

Health and safety activities at cooperating companies

Each production site holds regular Safety Conferences, aimed at preventing work-related accidents and disasters, with cooperating companies contracted for facility construction, manufacture, or logistics. At these meetings, we hear the views of cooperating companies and strive to enhance occupational health & safety management.

System

The system for occupational safety management is represented by the following diagram. For the composition of the ESH & QA Committee, please refer to Asahi Kasei Group’s ESH & QA > Management Framework

Occupational safety management system

Occupational safety management system

Preventive action for occupational accidents

Asahi Kasei Life Saving Actions (LSA)

In fiscal 2020, the Asahi Kasei Group established a Life Saving Actions (LSA) program to eradicate serious occupational accidents, and we began implementing it group-wide. We have established the following four behaviors as prohibited behaviors that could result in loss of life if not observed, and are promoting thorough adherence to these behaviors in all aspects of our business activities.

The four behaviors prohibited by LSA

The four behaviors prohibited by LSA

Occupational Health & Safety Management System

We have enacted Guidelines on Occupational Health & Safety Management System (OHSMS) in compliance with ISO 45001, and are promoting activities for health and safety at each workplace. The following workplaces have obtained ISO 45001 certification as of May 2025.

- Asahi Kasei Metals Corporation

- Ion Exchange Membranes Production Department, Kawasaki Works, Asahi Kasei Corporation

- Asahi-Schwebel Taiwan Co., Ltd.

- Thai Asahi Kasei Spandex Co., Ltd.

Initiatives in priority issues related to occupational accident prevention

In addition to maintaining the LSA program and occupational health & safety management as pillars in occupational safety, we are working on the following priority issues from the perspective of preventing serious accidents: 1. Preventing entanglement in machinery; 2. Chemical substance management; 3. Preventing heatstroke.

1. Preventing entanglement in machinery

In order to systematize mechanisms for the LSA prohibition on working close to moving parts, we are devoting energy to initiatives in machine safety.

Along with formulating company-wide standards for machine safety measures, we defined a company-wide standard that describes a method for specific machine risk assessment, and implement it at every workplace.

As part of promotion of machine safety, we have created a training program for every job level, implementing education for management, machine designers, safety personnel, and machine users involved in production.

In addition, aiming to objectively grasp our employees’ level of machine safety understanding and capability, as well as to spread the scope of machine safety thinking, we encourage the acquisition of Safety Assessor (SA) and Safety Sub Assessor (SSA) certifications recognized by the Japan Certification Corporation. The cumulative total of people who obtained certification by fiscal 2024 was over 50 for SA, and over 950 for SSA.

2. Chemical substance management

As a diversified chemical manufacturer, we consider ensuring the occupational safety for all tasks that handle chemical substances to be a priority issue. While complying with the Industrial Safety and Health Act and foreign and domestic laws related to chemical substance management, we implement chemical substance risk assessment at each production site. We intend to reduce exposure risks through internal deployment of information based on Safety Data Sheets (SDS), guidance on appropriately wearing personal protective equipment, preparation of local exhaust mechanisms, and preparation and renewal of work manuals.

In particular, there were significant changes following the revisions of the Industrial Safety and Health Act of May 2022, such as the requirement for business operators to autonomously manage chemical substances, so the Asahi Kasei Group is advancing with an appropriate response to those changes. We have held company workshops to foster chemical substance managers who are now required to be appointed at workplaces manufacturing risk-assessed substances. In fiscal 2023, we trained 329 chemical substance managers internally, and in fiscal 2024, we trained 76. Moving forward, we will work continuously on a more sophisticated chemical substance management system, and a workplace environment with even greater safety.

3. Preventing heatstroke

Along with the recent rise in temperatures, we have seen a trend of more accidents due to heatstroke at our company. As some cases of heatstroke become serious, we are working on countermeasures with this as a priority issue.

We position the on-site manager for each workplace as the key person for heatstroke countermeasures, and implement training for them as heatstroke prevention managers. We also measure Wet Bulb Globe Temperature (WBGT) at each site, and ensure that there is proper work management, breaks, hydration and salt intake. Also, we strive for heatstroke prevention that considers the different conditions of individuals.

Furthermore, we proactively adopt tools effective for heatstroke prevention, by supplying wearable devices and jackets equipped with cooling fans, in addition to managing the working environment, work operations, and health.

Education on occupational health and safety

In order to have each and every person acquire and utilize fundamental knowledge on safety, the Asahi Kasei Group systematically implements education on environment, safety, and health, including content on occupational health and safety, for on-site supervisors, ESH staff, and newly-appointed members.

| Name of training | Overview | FY2024 Number of trainees | |

|---|---|---|---|

| By rank | Safety training for new employees and those with six months of service | Online risk prediction training and group discussion | 349 |

| Environment, safety, and health training for assistant managers | Online lectures and test covering all of environment, safety and health, including occupational safety | 269 | |

| Safety training for Managers | Online lectures and test covering all of environment, safety and health, including occupational safety | 67 | |

| By subject | Machine safety training for General Managers and Managers | Online lectures for managers to understand the necessity of machine safety and their responsibilities as managers | 126 |

| Machine safety training for personnel | Training to learn risk assessment and risk reduction in regards to machine safety | 117 | |

| Specialized course for chemical substance managers | Face-to-face training to foster chemical substance managers in accordance with the curriculum set out by the Ministry of Health, Labour and Welfare | 76 | |

| Heatstroke lecture | Online lecture and archived distribution for on-site managers | 344 |

Sharing and utilizing information of occupational accidents

We investigate causes and take measures to prevent recurrence at sites where occupational accidents occur. We share a database of information on all occupational accidents within the Asahi Kasei Group for utilization in activities such as safety training, case study discussions, and prevention of similar accidents.

In addition, we are moving forward to create a dashboard of the database for greater utilization in safety activities.

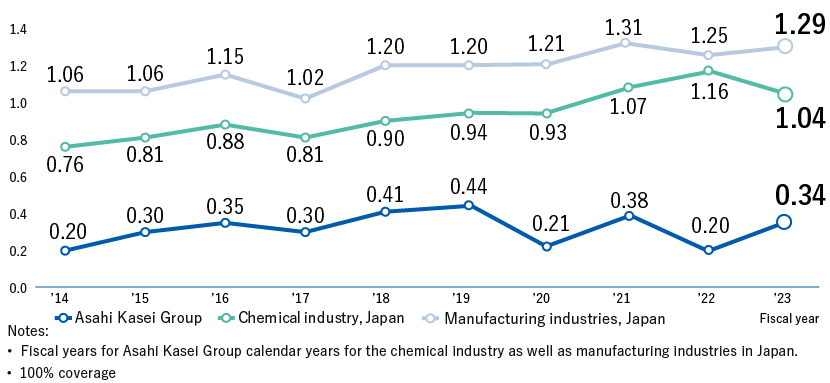

Occupational accident statistics

The number of lost-time injuries for employees at Asahi Kasei Group and cooperating companies domestically and foreign respectively for the past 5 years is shown in the table below. These injuries include cases like acting in violation of aforementioned LSA program. Specific examples are entanglement in machinery due to disobeying rules, falls due to not wearing the fall-prevention equipment (safety belts), etc. We are promoting continued safety activities, particularly the LSA program, as we engage in awareness-raising not only for domestic employees, but also for people in foreign and cooperating companies as well. The line charts below show the lost time frequency rates and severity rates for domestic employees of the Asahi Kasei Group.

Number of lost-time injuries

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Domestic employees | 12 | 22 | 12 | 20 | 19 |

| Domestic contractors | 11 | 14 | 13 | 14 | 29 |

| Overseas employees | 19 | 19 | 13 | 14 | 14 |

| Overseas contractors | 5 | 1 | 3 | 2 | 6 |

Group Lost Time Frequency Rate (%)1

Group Lost Time Frequency Rate (%)1

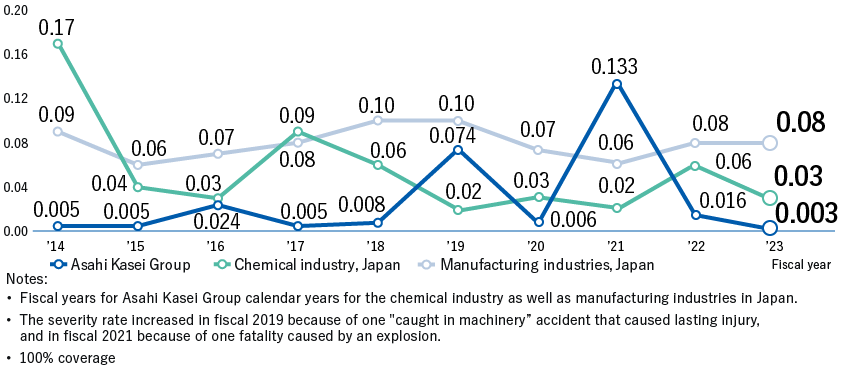

Group Severity Rate (%)2

Group Severity Rate (%)2

- 1

Lost Time Frequency Rate:

A safety indicator showing the rate of occupational accidents and calculated by the following formula. [Lost time frequency rate = number of victims of lost time injuries ÷ total working hours × 1,000,000 hours]

Our goal of 0.1 or less is extremely ambitious. At a plant with 100 workers, it would mean only one worker in 50 years suffered from an occupational injury which resulted in a day off. - 2 Severity rate: A safety indicator showing the severity of occupational accidents and calculated by the following formula. [Severity rate = number of working days lost ÷ total working hours × 1,000 hours]

Health & Productivity Management Policy

Human resources are the essential element for the sustainable growth of corporate value. Providing an environment that supports the physical and mental well-being of employees is becoming increasingly crucial for corporations.

Therefore, we have developed existing Environment, Safety, Health, and Quality Assurance activities, positioning health-related initiatives as a company-wide management issue, and we published the Asahi Kasei Group’s “Statement on Management for Health.” Therefore, we will work to further promote health and productivity management* based on the Asahi Kasei Group Health and Productivity Management Vision described in the Statement.

Currently, we are further enhancing our programs for the prevention of mental health issues, which is a priority in our PDCA cycle, as defined in the health and productivity management goals of our medium-term plan. Furthermore, we will promote Well-being Management that aims for a state of joy that benefits employees physically, mentally, and socially, by establishing health and productivity management targets and crafting individual countermeasures for management issues we would like to solve for the advancement of health and productivity management.

- *In Japanese “Kenkokeiei” is a registered trademark of Nonprofit Organization Kenkokeiei.

Statement on Management for Health

The Asahi Kasei Group pursues sustainable growth of corporate value while contributing to the achievement of a sustainable society by leveraging its strengths of diversity and the capability to change. We believe that human resources are the key to achieving this goal.

In the future, it will become ever more important for the company to create an environment where employees can both physically and mentally healthy and where everyone can play an active role. We hereby declare that we will work to promote health and productivity management, which further refines the initiatives for promoting and maintaining health we have developed to date, under our Group Health and Productivity Management Vision.

October 2020, Asahi Kasei Corp.

The Asahi Kasei Group Health & Productivity Management Vision

Health and Productivity Management Vision

The Asahi Kasei Group will contribute to the achievement of a sustainable society by encouraging the active participation and growth of each individual and the improvement and development of Group productivity. To this end, the company will ensure that its employees and their families are both physically and mentally healthy, and strive to enhance their job and life satisfaction.

Behavioral Guidelines

- 1.The company will work in tandem with health insurance companies and labor unions, to not only continuously support individual workers, but also engage in various activities, including workplace activities, that maintain and promote environmental improvement for the entire Asahi Kasei Group, and the good health of families that support employees.

- 2.It’s also important for each individual to be aware that they are responsible for their own health, in order to enrich their own lives, and we provide support to help them achieve this.

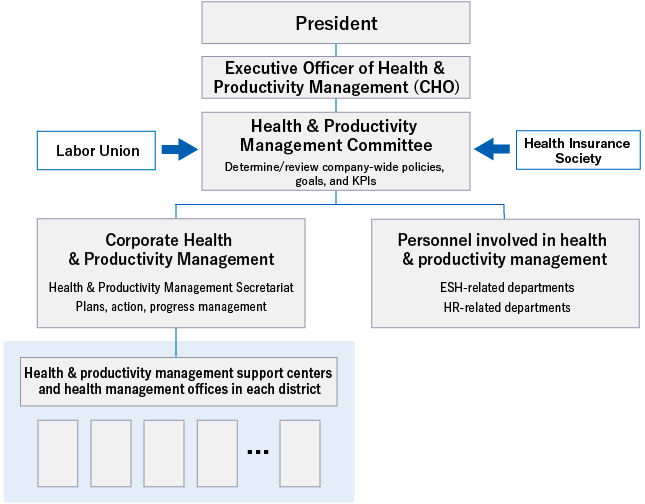

Promotion framework for health & productivity management

In January 2020, we established the Corporate Health and Productivity Management, and in April 2021, our nine Health Management Centers in Japan became affiliated with the head office. This enabled us to standardize and optimize overall health-related operations, improve coordination among different sites, and promptly address group-wide challenges, with unified promotion of health and productivity management. Furthermore, we started Health and Productivity Management at our small-scale establishments and affiliated companies in Japan from April 2022.

Under the leadership of the President, we are building a system overseen by the Executive Officer of Health & Productivity Management (CHO), and working on the promotion of company-wide health and productivity management. The Health & Productivity Management Committee formulates policies, and sets and examines KPIs for the purpose of enhancing corporate value, whereas Corporate Health and Productivity Management bears the responsibility of planning, implementing, and managing the progress of these policies and KPIs. Furthermore, we are aiming for sustainable growth through maintenance and improvement of employees’ health by facilitating collaboration between the labor union and the health insurance society, and cooperation between relevant divisions, including ESH and HR departments.

Promotion framework for health & productivity management

Promotion framework for health & productivity management

Purpose of health & productivity management

We aim for a mutually reinforcing cycle of sustainability consisting of contributing to a sustainable society and sustainable growth of corporate value, by creating a synergy among the success and growth of each individual, enhanced job satisfaction and motivation, and a strong and vibrant organizational culture based on the promotion and maintenance of the physical and mental health of employees and their families, which will lead to the realization of employee well-being and the increased and enhanced productivity of the Asahi Kasei Group.

Overview of health & productivity management

Overview of health & productivity management

Health & Productivity Management Strategy Map

For the promotion of health and productivity management, we believe it is necessary to clearly grasp what kind of investment and policy measures will address management issues, and what effects they will bring. Therefore, we visualize the targets and expected results of each measure, as well as their connection to specific initiatives, by establishing a Health & Productivity Management Strategy Map, as we aim for strategic and continuous health and productivity management.

This map focuses on priority measures, such as creating opportunities for employees to be active and grow, revitalizing individuals and organizations, and improving the quality and amount of sleep and shows the pathway to balancing attainment of well-being through health maintenance and improvement with enhanced productivity led by health and productivity management. It serves as a basis for explaining to internal and external stakeholders the relationship between our purpose of health & productivity management and specific initiatives.

Health & Productivity Management Targets (Priority Measures)

To achieve our health and productivity management targets, we believe it is important both to create opportunities for employees to be active and grow, and to revitalize individuals and organizations.

To create opportunities for employees to be active and grow, we will reduce the number of days employees take off work. In addition to this, we will work on revitalizing individuals and organizations.

From the perspective of improving productivity, we will also strive to help employees get more and better-quality sleep, a lack of which is said to be a major contributing factor behind “presenteeism.”

For this reason, the Asahi Kasei Group has set its primary health and productivity management goals as follows: (1) creation of opportunities for employees to play an active role and grow, etc. (reducing absence rate (absenteeism) through countermeasures for mental health issues, people with serious lifestyle-related diseases, people with metabolic syndrome, cancer, and smoking); (2) improving the quality and quantity of sleep (reducing presenteeism); and (3) revitalizing individuals and organizations (improving work engagement).

(3) Regarding the revitalizing individuals and organizations (improving work engagement), the Asahi Kasei Group conducts annual stress checks in July to promote awareness among employees of their own stress levels with the aim of primary prevention to reduce the risk of mental health problems. In fiscal 2020, we also adopted the KSA (vitality and growth assessment) survey, which enables more detailed analysis and visualization of work engagement (enthusiasm, immersion, and vitality) in workplaces. KSA quantitatively visualizes workplace conditions according to three indicators: (1) supervisor–subordinate relationships and workplace environments, (2) vitality, and (3) action driving growth.

Each workplace is currently striving to improve work engagement by combining the results of the stress check and KSA analysis to visualize management and other initiatives implemented, and to have employees at each workplace engage in dialogue with each other.

Primary health and productivity management target items

| Item | FY2019 Results |

FY2020 Results |

FY2021 Results |

FY2022 Results |

FY2023 Results |

FY2024 Results |

FY2024 Target4 |

|

|---|---|---|---|---|---|---|---|---|

| Reducing absence rate (absenteeism) | Percentage of employees absent from work due to mental health Issues1 | 0.91 | 0.98 | 1.00 | 1.07 | 1.16 | 1.20 | 0.64 |

| Percentage of employees seriously ill with lifestyle-related diseases2 | 11.0 | 11.0 | 10.7 | 10.7 | 9.9 | 10.0 | 7.7 | |

| Percentage of employees suffering from metabolic syndrome | 11.1 | 11.4 | 11.1 | 10.7 | 10.8 | 11.0 | 7.8 | |

| Number of days off per cancer case | 79.2 | 68.1 | 87.5 | 88.6 | 67.3 | 82.7 | 67.3 | |

| Smoking rate (%) | 25.8 | 24.7 | 23.5 | 22.5 | 21.8 | 20.2 | 15.5 | |

| Reducing presenteeism | Percentage of workers not getting enough rest through sleep | 32.4 | 28.5 | 27.2 | 28.0 | 28.5 | 29.8 | 22.7 |

| Improving work engagement | Vitality (Engagement)3 | ― | ― | 3.54 | 3.54 | 3.55 | 3.57 | ― |

- Note: Scope of subjects: Asahi Kasei Corp., Asahi Kasei Microdevices Corp., Asahi Kasei Homes Corp., Asahi Kasei Construction Materials Corp., Asahi Kasei Pharma Corp., Asahi Kasei Life Science Corp., and certain subsidiaries and affiliates

- 1Percentage of employees who are absent from work for 30 or more consecutive days during the fiscal year

- 2Selected based on in-house criteria

- 3On a scale of 1 to 5

- 4Medium-term target as of 2020

Specific initiatives

Mental health and care

The Asahi Kasei Group is working to reduce the rate of employees missing work due to mental health issues in accordance with its Mental Health Care Guidelines. To reduce the number of employees on sick leave due to mental health issues, we have our occupational health staff analyze the trends and characteristics of the causes and backgrounds of these absences from the interview results on a district-by-district basis. They determine contributing factors by considering both direct causes and background information obtained from interviews. Results from each site are also aggregated, with company-wide data analyzed according to various aspects such as job category and position, which are then shared throughout the company, and for which countermeasures are created.

(1) Self-care measures

To promote understanding of stress and how to cope with mental health-related issues, we have been implementing and improving the training on mental health. Since 2023, we have provided mental health self-care training annually to all domestic Asahi Kasei Group employees (approximately 30,000 employees) to help them recognize and manage their own stress and mental health issues at an early stage. Also, three months later, we implement a survey on changes in behavior to measure the staying power of the training.

(2) Care by line of authority

As part of the line-based care, we use the results of organizational analysis of stress checks and training courses to improve the work environment. We have been offering workshops in collaboration with human resources departments, occupational health staff and the labor unions, using the stress check and KSA results in an integrated manner.

(3) Care by occupational health staff and others

We have conducted a program called “Follow-up Care for Transferred Employees,” in which we monitored how they were adjusting to new environments and workplaces, with the aim of preventing the condition from worsening by providing early treatment to employees who show signs of illness.

We conduct the follow-up via questionnaires and interviews in which transferred employees confirm their health status and how they have adapted to their new roles and living environment, and make early intervention. The results are fed back to workplaces as necessary to support the creation of workplaces that prevent the onset of mental illness. Starting in fiscal 2024, we began deployment company-wide, with a follow-up rate for transferred employees of 99.3%. Moving forward, we will measure efficacy with early follow-ups for employees who have experienced changes in their environment.

(4) Care by specialized organizations

Rework programs are also available for those who took a leave of absence due to mental health issues, as part of the rework trial designed to help them resume their roles successfully. In addition, we provide care by specialists, including training sessions by external lecturers and referral of counseling services.

Cancer awareness initiatives

(1) Education to improve cancer literacy

We provided a company-wide e-learning program to all domestic Asahi Kasei Group employees, focusing on cancer prevention and promotion of a better work-life balance. The program aimed to educate employees about cancer, promote healthier lifestyles that can reduce the risks of cancer, and encourage regular cancer screenings for early detection and treatment.

Additionally, we invited lecturers who had experienced cancer to give company-wide online seminars on the theme of “How I Can Prepare Today,” so that employees would consider the possibility of working even if they have cancer. Including on-demand participants, 585 employees attended the seminar, and 97% of them responded “highly satisfied” or “satisfied” with the content of the lecture.

We also had a gynecologist from Cancer Institute Hospital give a lecture on “Women's Cancers” as part of our health measures for women, and the video is available on the company intranet.

(2) Recommendation for cancer screening

We encourage cancer screening during regular health checkups or physical exams, with some of the expenses covered. We also make sure our employees are familiar with our support programs for those who undergo cancer treatment and return to work after their leave.

Initiatives for employees with severe lifestyle-related diseases and metabolic syndrome

In order to maintain and improve the health of our employees, the Asahi Kasei Group is working to prevent and address lifestyle-related diseases.

(1) Specific health guidance and Get Fit Challenge

Our company-wide policy on specific health guidance is that, in principle, employees must attend a consultation unless they have a valid reason not to, and may also receive the guidance during work hours.

We have also expanded the program’s scope with the “Get Fit Challenge” to include previously ineligible employees, which has helped to prevent lifestyle-related diseases from an early stage.

(2) Creation of exercise occasions

Each production site organizes walking events, as well as annual physical fitness tests to monitor the changes over time. Also, exercise videos that are easy for anyone to do anywhere are available on an internal website to encourage employees to start exercising.

Actions to promote exercise habits at each site

To prevent the development of serious lifestyle-related diseases and metabolic syndrome, we host walking events and physical fitness tests at each production site as part of our efforts to promote regular exercise.

Utilizing a walking app, we encourage participants to change their behavior, raise health awareness, and foster communication, even in work-from-home settings. In some districts, we hold a “Mystery and Health Walk” as a recreational activity, with a quiz rally where participants search for quizzes walking within the production site's premises, with the intention of increasing the number of steps while having fun.

Creation of exercise videos to establish exercise habits

We have created videos of simple exercises that can be easily done at home, at one’s desk, etc., and posted them on an internal website.

The Asahi Kasei Judo Team and Office District Health Management collaborated to create simple stretching videos that can be followed during office hours to refresh employees who work continuously at their desks, and to help them establish exercise habits. Programs devised by Judo Team members, who are experts on physical maintenance, were edited into short videos for use in both a personal capacity and in the workplace.

Stretching video created by the Asahi Kasei Judo Team

Stretching video created by the Asahi Kasei Judo Team

Efforts to Reduce the Smoking Rate

We have implemented a total ban on smoking during working hours from April 2024, and then to ban smoking completely on company premises and during banquets* from April 2025. This is in line with the Asahi Kasei Group No-smoking Policy, whose basic concept is supporting smokers to quit smoking and protecting employees from unwanted passive smoking.

Besides the Smoking Cessation Challenge organized and implemented by the Asahi Kasei Health Insurance Society, we will provide a variety of quit smoking programs and seminars to help smokers refrain from smoking.

- *No smoking during banquets: Those who leave the dining area to smoke are not permitted to re-enter.

Sleep Improvement Program

We launched a project to establish sleep strategies, as the quality and quantity of sleep is considered to be a major cause of presenteeism after mental health issues.

For our Sleep Strategies Project, we have continuously been providing the Sleep Improvement Program, as 80% of participants recognized that their sleep had improved due to the program. We recognize that sleep strategies are particularly challenging for shift workers, and have created videos to introduce sleep strategies into their training curriculum. Starting in June 2025, we have been implementing a company-wide survey on sleep.

Education on Health & Productivity Management

To support employees in acquiring knowledge and skills for health and productivity management, we provide a number of training programs based on the job roles for the various employee ranks.

| Training | Method of Training | Purpose | FY2024 Number of trainees |

|

|---|---|---|---|---|

| Training by rank | New employee training | e-learning Face-to-face training |

Understand the basic health concepts as a responsible member of society, commit to physical and mental self-conditioning, precautions for handling hazardous materials, and necessary company rules, etc. | 277 people |

| Training for new assistant managers | e-learning | Basic concept of work and health, company and employee obligations in health management. | 329 people | |

| Training for new managers | e-learning | Health management services, including hazardous work and occupational disease prevention necessary for on-site management, and understanding of the Asahi Kasei Group’s overall health and productivity management, and its importance. | 285 people | |

| Environment, safety, health training for Managers | Online | Management of hazardous materials handling operations at manufacturing sites. | 67 people | |

| Training by Subject | e-learning | Mental Health Self-care | 27,710 people (96.2%*) | Education on health and productivity management | 27,091 people (94.4%*) |

- *Percentage of participants who are eligible for the training

Initiatives other than priority measures

Women health measures

Supporting the health of women so they can continue to work and demonstrate their abilities during life events such as pregnancy, delivery, and child care, regardless of the presence of health problems, is very important.

We broadcast information aimed at enhancing the literacy of women’s health, and have created educational content on the health of working women, which is published on the company’s intranet.

In addition, as part of our support for health, we encourage cancer screenings, and implement one uterine cancer screening and one breast cancer screening every two years at the company’s expense. The screening rate was 73.6% for breast cancer and 59.4% for cervical cancer in fiscal 2024. We are currently aiming to achieve a screening rate of over 60% at all sites.

At the WA space in the Women’s Pavilion in collaboration with Cartier at EXPO 2025 Osaka, Kansai, Japan, the “Global Women’s Body Conference 2025” was held on the theme of how future healthcare can contribute to the empowerment of women, with the Asahi Kasei Group receiving the Grand Prize.

Health Management Support for Overseas Employees

The Asahi Kasei Group is strengthening health management of our employees working overseas, who are increasing in number as our business expands globally.

We provide pre-transfer medical checkups, vaccinations, prescriptions of anti-influenza medication in advance to prepare for a novel influenza pandemic, and pre-transfer health education, as well as annual medical checkups throughout employees’ assignments and a post-transfer medical checkup including for accompanying family members requested upon their return.

During an assignment, a web interview with an industrial physician is conducted. For overseas employees, we conduct the stress check in the same way as employees working in Japan. In addition, we also use a health survey form to assess symptoms, local lifestyles, mental and physical health, and vaccination status. Based on the questionnaire results and medical exams, we schedule online interviews with our industrial physician or health advisor as required.

Moreover, for employees working overseas who are suspected of working long hours, online interviews with industrial physicians are conducted based on the medical interview results.

“Health Letter from Tokyo” is regularly distributed to expatriates as well, providing information such as health checkup results and lifestyle questionnaires, and health information, all compiled by region. We also provide health counseling for other health concerns and problems.

Activity evaluation and recognition by external organizations

Recognized as White 500 (large enterprise category) in the Certified Health and Productivity Management Organization Recognition Program 2025

We were recognized for the third year running as one of the “White 500” organizations under the 2025 Outstanding Organizations of KENKO Investment for Health (Large Enterprise Category), jointly operated by the Ministry of Economy, Trade and Industry (METI), and Nippon Kenko Kaigi. The Certified Health and Productivity Management Organization Recognition Program acknowledges corporations for their exceptional health and productivity management practices, aligned with community health agendas and health promotion activities advocated by the Nippon Kenko Kaigi.

Received the Gold Prize in the Cancer Ally Awards 2024

We received the Gold Prize in the 2024 Cancer Ally Awards, sponsored by a non-governmental organization dedicated to addressing cancer and issues of those who are receiving cancer treatment while continuing their career. This project aims to create a society and workplace environment that empowers cancer patients to maximize their potential while undergoing treatment.

Certified as a Sports Yell Company of 2025

We have been certified as a Sports Yell Company of 2025 by the Japan Sports Agency. This program aims to encourage the involvement of prime-age workers in sports and generate a societal interest in physical activities. It will grant certification to companies that actively promote sports to improve their employees’ health. We were recognized for our efforts in providing exercise videos, athletic facilities, and walking events held at each of our sites.